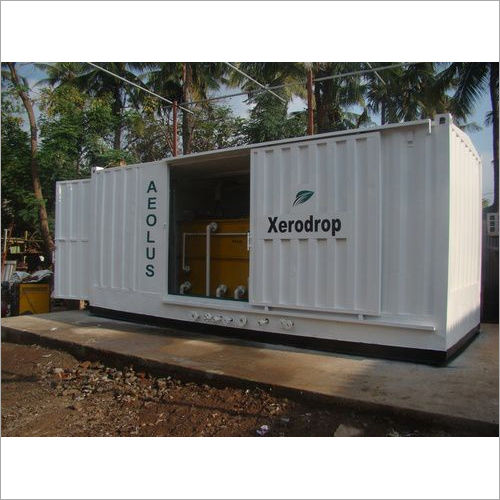

Effluent Treatment Plant ETP Compact packaged prefabricated

Price 200000 INR/ Plant

Effluent Treatment Plant ETP Compact packaged prefabricated Specification

- Membrane Quantity

- No membrane required

- Application

- Industrial complex and hazardous wastewater treatment

- Product Type

- Effluent Treatment Plants

- Technology

- XERODROP- Non biological ETP STP Wastewater treatment

- Operation Type

- Semi Automatic

- Warranty

- 1 year

Effluent Treatment Plant ETP Compact packaged prefabricated Trade Information

- Minimum Order Quantity

- 1 Plant

- Supply Ability

- 10 Plants Per Month

- Delivery Time

- 6 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- Himachal Pradesh, Manipur, Pondicherry, Uttarakhand, Dadra and Nagar Haveli, South India, North India, East India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Delhi, Bihar, Chhattisgarh, Chandigarh, Daman and Diu, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Nagaland, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Lakshadweep, All India, Uttar Pradesh, Gujarat, Central India, Odisha, West India

About Effluent Treatment Plant ETP Compact packaged prefabricated

Aeolus is engaged in indigenous Research and Development on complex and hazardous effluent treatment since 2009. Our treatability limits now are up to 5,00,000 ppm of COD.

We prefer not using chemicals as far as possible. None of our installed systems to date has any conventional processes like aeration!

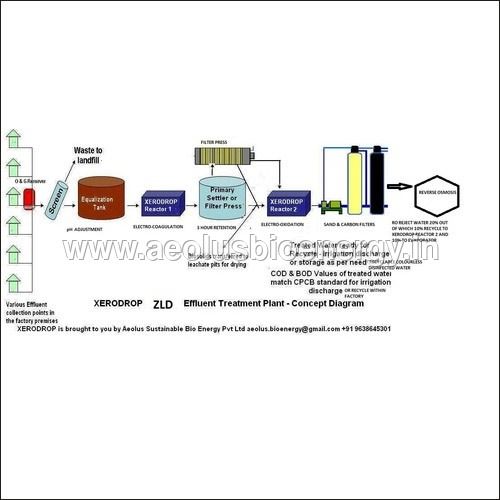

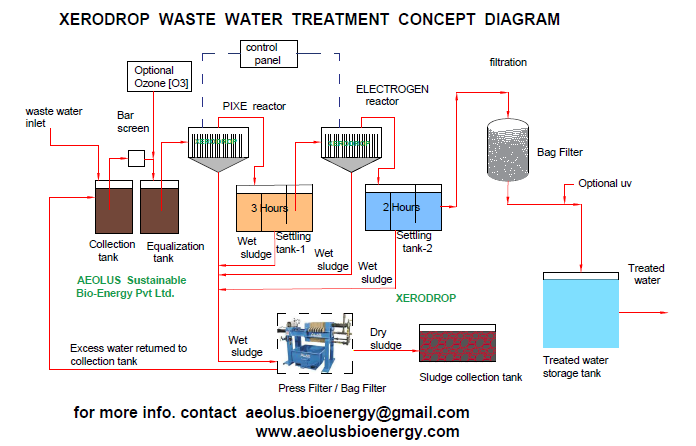

The technologies we employ include Electro-Chemistry (Electro-Coagulation, Electro-Oxidation, Electro-Floatation), AOP Advanced Oxidation Processes (O3/UV/H2O2) and Natural Botanical Extracts. With this simple list of technologies, we have worked wonders for most complex effluents.

We have a database of more than 400 complex industrial effluents that are treatable with our technologies. We also undertake treatability testing and pilot testing at nominal cost for the client.

Effluent containing complex organic compounds with cyclic or linear structures, formaldehyde, acetic acids, alcohol, oils, chlorophenols, nitrophenols, nitrotoluenes, H Acid, J Acid, molasses distillery spent wash, winery effluents, tannery effluents, dairy whey effluents, resin production effluents, textile, chemical, pharmaceutical, dyes & intermediate, food colour effluents are treatable with our system.

Your details are safe with us and we dont share them with anybody.

Contact us for more information. We are the final destination of your search for effective and efficient effluent treatment for your industry.

Advanced Non-Biological Wastewater Treatment

The XERODROP technology powers this ETP with a non-biological treatment mechanism, effectively processing hazardous wastewater without the need for membranes. It offers a robust performance for industrial environments where traditional systems may be less effective or require ongoing biological maintenance.

Semi-Automatic Operation for Ease of Use

Efficient semi-automatic controls streamline operations, allowing for intuitive management by facility staff. This minimizes the need for specialist knowledge and reduces operator intervention, optimizing daily workflow and ensuring consistent treatment quality.

FAQs of Effluent Treatment Plant ETP Compact packaged prefabricated:

Q: How does the XERODROP non-biological technology treat hazardous wastewater in this ETP system?

A: XERODROP technology utilizes advanced electrochemical and physical processes to break down contaminants in industrial and hazardous wastewater without relying on biological agents, making it highly effective for challenging effluent types.Q: What is the process involved in operating the semi-automatic compact ETP unit?

A: The semi-automatic operation involves simple startup procedures, monitoring key parameters, and periodic checks by the operator. The system automates core treatment stages, requiring minimal manual adjustment during daily use.Q: When is it advisable to use this compact packaged ETP system?

A: This system is ideal for industrial facilities and complexes dealing with hazardous wastewater streams, particularly where traditional biological ETPs are not suitable or effective for specific pollutants.Q: Where can the prefabricated ETP unit be installed?

A: Designed for flexibility, the compact and prefabricated ETP can be installed at industrial sites, manufacturing plants, chemical factories, and hazardous waste generation points across India.Q: What benefits does the absence of membranes offer in this ETP system?

A: Eliminating membranes reduces operational complexity, maintenance costs, and the risk of fouling or frequent replacements, ensuring reliable long-term performance against hazardous contaminants.Q: How can users benefit from the 1-year warranty included with the ETP package?

A: The one-year warranty provides assurance regarding quality, support for troubleshooting, and prompt service assistance from the manufacturer, safeguarding your investment during the initial operational period.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Effluent Treatment Plants Category

Electro-Coagulation Electro-Oxidation Electrolytic System from Aeolus

Price 200000 INR / Plant

Minimum Order Quantity : 1 Plant

Operation Type : Semi Automatic

Product Type : Effluent Treatment Plants

Power Source : Electric

Membrane Quantity : Module based (variable)

Compact ETP STP

Price 200000 INR / Plant

Minimum Order Quantity : 1 Plant

Operation Type : Automatic

Product Type : Other, ETP STP Compact Unit

Power Source : Electric

Membrane Quantity : 2 to 10 units (Depends on Capacity)

Fertilizer Industry Effluent Treatment

Price 366000 INR / Unit

Minimum Order Quantity : 1 Unit

Operation Type : Semi Automatic

Product Type : Effluent Treatment Plants

Power Source : AC

Membrane Quantity : no membranes required

Textile Effluent Treatment Plant

Price 200000 INR / Plant

Minimum Order Quantity : 1 Plant

Operation Type : Semi Automatic

Product Type : Effluent Treatment Plants

Power Source : AC

Membrane Quantity : no membranes required

Send Inquiry

Send Inquiry