Fertilizer Industry Effluent Treatment

Price 366000 INR/ Unit

Fertilizer Industry Effluent Treatment Specification

- Capacity

- 1000 liters and more per day Kg/hr

- Application

- complex and hazardous wastewater treatment

- Membrane Quantity

- no membranes required

- Product Type

- Effluent Treatment Plants

- Technology

- Non biological electrochemistry-based wastewater treatment plant electrocoagulation and electrooxidation with advanced oxidation processes

- Power Source

- AC

- Operation Type

- Semi Automatic

- Warranty

- 1 year

Fertilizer Industry Effluent Treatment Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- compact skid mounted or containerized plants

- Main Export Market(s)

- Africa, Asia, Eastern Europe, Middle East

- Main Domestic Market

- Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, South India, North India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Tripura, Nagaland, West Bengal, Lakshadweep, Uttar Pradesh, Haryana, Telangana, Kerala, Central India, Odisha, West India, Chhattisgarh, All India

About Fertilizer Industry Effluent Treatment

Fertilizer Industry Effluent Treatment

Fertilizer industry is very important manufacturing sector, especially for India due to its agricultural economy. Industrial waste water treatment is a complex problem for a variety of highly polluting chemical industries such as fertilizer, distillery, dyes and pigment, textile etc. Major pollutants in the fertilizers waste water for which the treatment is necessary include oil, arsenic, ammonia, urea, phosphate and fluoride. Waste water treatment is a major problem in such complex fertilizer plants from an environmental pollution point of view.

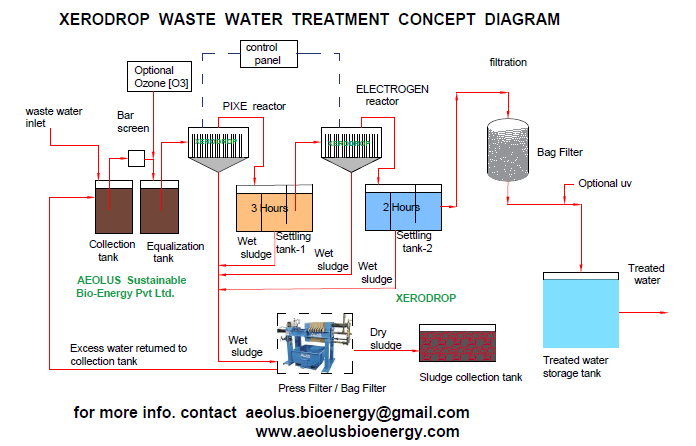

So, AEOLUS introduces Fertilizer Industry Effluent Treatment to treat such kind of Effluent. XERODROP is a method which is simple but very effective for the treatment of turbid water and waste water. Aeolus has spent more than four years with untiring rigorous efforts implementing & restructuring the technology to treat highly recalcitrant effluents like distillery spent wash.

XERODROP has also provided extra ordinary results in treating effluents such as that from pharmaceuticals, food processing units, Dairy, oil refineries, textiles and thermal power plants. XERODROP is engineered to follow the toughest discharge norms. The treated water is fit for entire non-potable requirements of industries as well as agriculture.

Advantages:

- Low sludge generation

- No dependency on Bacteria- no culture-no activated sludge-no aeration-no membranes

- More than 90% water recovery for recycle and irrigation

- Treated effluent is colorless, odorless and the BCOD of highly recalcitrant effluents are reduced to comply with stringent PCB norms for discharge.

- Generated sludge is a rich fertilizer and micro nutrient supplement-extra revenue for the client!

We treat waste water with COD up to 200000 ppm and even more. So, your effluent is treatable with XERODROP ETP. Contact us now!

Product Details:

|

Feed Flow Rate |

01 to 1000 m3/day, |

|

Usage/Application |

Waste water treatment & hazardous effluent treatment plant |

|

Water Source |

Commercial Waste Water, Municipal Sewage, Industrial Effluent, Hazardous Effluents |

|

Treatment Technique |

Electro-chemistry and advanced oxidation process |

|

Type |

Waste Water Treatment |

|

Condition |

New |

|

Treated Water Quality |

As per CPCB discharge Norms |

|

Treatment Stages |

Tertiary Treatment, Primary Treatment, Electro-Coagulation, Electro Oxidation, Electro-Floatation, Ozone, UV, Secondary Treatment, Disinfection |

|

Installation Type |

Prefabricated, Containerized Plug & Play |

|

Features |

Containerized waste water treatment plant |

|

Overall Dimensions |

20 ft and 40 ft standard cargo containers |

|

Manufacturing Lead Time |

8-12 weeks |

|

Material of Construction |

FRP, MS |

|

Control Module |

Control Module Available |

|

Filtration System |

Micron filters |

|

Industry |

Distillery |

|

Plant Type |

Wastewater Treatment Plant |

|

Application |

sewage, Effluent and hazardous waste water treatment |

Advanced Electrochemical Wastewater Treatment

This treatment plant utilizes a non-biological approach, combining electrocoagulation and electrooxidation with advanced oxidation to tackle even the toughest industrial effluents. Its design ensures high efficiency in degrading hazardous organics and removing heavy metals, without relying on costly membrane filtration, making it highly suitable for fertilizer manufacturing units.

Reliable, Cost-Efficient Operation

Built for 24/7 industrial use, this semi-automatic plant is engineered for ease of operation and maintenance. The absence of membranes reduces replacement costs, while AC power ensures consistent performance. The systems robust design and 1-year warranty offer peace of mind to plant operators concerned with reliability and long-term operational efficiency.

FAQs of Fertilizer Industry Effluent Treatment:

Q: How does the fertilizer industry effluent treatment plant work without membranes?

A: The system uses advanced electrochemistryincluding electrocoagulation, electrooxidation, and advanced oxidation processesto physically and chemically remove contaminants, eliminating the need for membrane filtration. This approach also reduces maintenance complexities associated with membrane systems.Q: What types of wastewater can this plant treat?

A: This treatment plant is specifically designed for the fertilizer industry, capable of processing complex and hazardous wastewater streams that typically contain difficult-to-treat chemicals, organics, and heavy metals.Q: When is this treatment solution most beneficial?

A: This system is most beneficial when dealing with high-load industrial effluents where traditional biological or membrane-based methods struggle. Its chemical-based approach excels in treating toxic or persistent pollutants common in fertilizer manufacturing.Q: Where is this treatment plant manufactured and installed?

A: The plant is manufactured in India and can be installed at fertilizer factories or industrial sites within India or internationally, depending on requirements.Q: What is the process involved in treating the effluent?

A: Effluent first undergoes electrocoagulation, where contaminants aggregate and precipitate out. This is followed by electrooxidation and advanced oxidation processes, which break down and neutralize hazardous substances, ensuring clean, compliant discharge.Q: How is the plant operated and what power source is required?

A: Operation is semi-automatic, offering a balance between automation and manual oversight for optimal control. The plant runs on standard AC power, making integration with existing industrial infrastructure straightforward.Q: What are the main benefits of using this effluent treatment technology?

A: Major benefits include effective removal of diverse, stubborn contaminants, reduced operating costs due to membrane-free design, simplified maintenance, reliable performance, and assurance with a 1-year warranty.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Effluent Treatment Plants Category

Electro-Coagulation Electro-Oxidation Electrolytic System from Aeolus

Price 200000 INR / Plant

Minimum Order Quantity : 1 Plant

Operation Type : Semi Automatic

Warranty : 1 year

Product Type : Effluent Treatment Plants

Technology : XERODROP Non biological

Paint and Dye Industry Effluent Treatment by Aeolus

Price 150000 INR / Plant

Minimum Order Quantity : 1 Plant

Operation Type : Semi Automatic

Warranty : 1 year

Product Type : Effluent Treatment Plants

Technology : XERODROP Non biological Effluent treatment

Textile Effluent Treatment Plant

Price 200000 INR / Plant

Minimum Order Quantity : 1 Plant

Operation Type : Semi Automatic

Warranty : 1 year

Product Type : Effluent Treatment Plants

Technology : ElectroCoagulation Electro Oxidation and Ozone non biological treatment

Industrial Wastewater Treatment Plant ETP STP

Price 366000 INR / Unit

Minimum Order Quantity : 1 Unit

Operation Type : Semi Automatic

Warranty : 1 year

Product Type : Effluent Treatment Plants

Technology : XERODROP Non biological wastewater treatment

Send Inquiry

Send Inquiry