Tea Leaf and Coffee Bean Processing with Ozone

Price 45000 INR/ Plant

Tea Leaf and Coffee Bean Processing with Ozone Specification

- Voltage

- 220 Volt (v)

- Product Type

- Tea Leaf & Coffee Bean Processing with Ozone

- Material

- Stainless Steel

- Capacity

- 250 Kg/hr

- Ozone Density

- 30 g/h

- Sterilizer Rate

- >99%

- Power

- 2.2 kW

- Frequency (MHz)

- 50 Hertz (Hz)

- Size

- Standard

- Weight

- 180 Kilograms (kg)

- Dimension (L*W*H)

- 1810 x 850 x 1180 mm

- Ozone Generator Type

- Integrated High-Efficiency

- Compliance Standard

- ISO Certified

- Safety Features

- Automatic Overload Protection

- Noise Level

- < 60 dB

- Finish

- Corrosion Resistant Smooth Finish

- Ozone Input

- Pure Oxygen

- Control System

- PLC Automatic Control

- Installation Type

- Floor Mounted

- Application

- Sterilization and Deodorization of Tea Leaves & Coffee Beans

- Operating Temperature

- 5C 50C

- Operation

- Continuous

Tea Leaf and Coffee Bean Processing with Ozone Trade Information

- Minimum Order Quantity

- 1 Plant

- Main Export Market(s)

- Asia, South America, Eastern Europe, Middle East, Africa, Western Europe

About Tea Leaf and Coffee Bean Processing with Ozone

The Ozone Advantage in Tea leaf and Coffee Bean Processing units:

1. Natural and Chemical-Free Solution: Ozone is an all-natural oxidant, leaving no chemical residues or harmful by-products on tea leaves or Coffee beans. It upholds the purity and authenticity of the final product.

2. Complete Microbial Control: Ozone's potent antimicrobial properties effectively eliminate bacteria, molds, and yeast present on tea leaves and coffee beans, ensuring they remain free from contamination.

3. Preservation of Aroma and Flavour: Ozone selectively breaks down unwanted compounds while preserving the delicate aroma and flavour characteristics of tea and coffee.

4. Extended Shelf Life: By reducing microbial load and inhibiting enzymatic reactions, ozone treatment extends the shelf life of tea leaves and coffee beans, minimizing product waste.

5. Versatile Applications: Ozone can be applied at various stages of processing, including drying, storage, and packaging, ensuring comprehensive and consistent quality control.

Ozone Applications in Tea Leaf Processing:

1. Pre-Drying Treatment: Ozone treatment before the drying process ensures surface disinfection, minimizing microbial contamination during drying.

2. Post-Drying Preservation: Ozone treatment after drying prevents post-processing microbial growth, enhancing shelf life and retaining freshness.

3. Flavour Enhancement: Ozone selectively targets undesirable compounds, allowing the natural flavours and aroma of tea leaves to shine through.

Ozone Applications in Coffee Bean Processing:

1. Pre-Roasting Treatment: Ozone treatment before roasting ensures microbial control and aids in preserving the authentic flavour of coffee beans.

2. Post-Roasting Preservation: Ozone treatment after roasting prevents post-roast contamination, maintaining the aroma and quality of coffee beans.

3. Reduction of Mycotoxins: Ozone's oxidative action effectively reduces mycotoxins, making coffee safer for consumption.

Power of Ozone over Current Practices:

1. Superior Quality Control: Unlike conventional methods, ozone ensures consistent and precise control over microbial contamination, flavour, and aroma retention.

2. Chemical-Free Purity: Ozone offers a chemical-free alternative, aligning perfectly with the growing demand for organic and clean-label products.

3. Enhanced Shelf Life: Ozone extends the shelf life of tea leaves and coffee beans, reducing product waste and enhancing marketability.

4. Energy Efficiency: Ozone requires less energy compared to conventional methods, making it an eco-conscious choice for sustainable processing.

Technical Expertise and Support: At Aeolus, we specialize in delivering advanced ozone-based solutions for tea leaf and coffee bean processing. Our team of experts collaborates closely with tea and coffee processors to design customized ozone systems that optimize processing stages and enhance product quality.

Experience the Ozone Transformation: Unlock the potential of ozone to revolutionize tea and coffee processing. Embrace a future where the purity and authenticity of your products take centre stage. Contact Aeolus today to explore how our ozone solutions can elevate your tea and coffee offerings and lead you towards a more prosperous future.

Elevate Your Beverage Excellence: Join the ranks of industry leaders who have harnessed the power of ozone to redefine tea and coffee processing. Together, let's pioneer a new era of purity and flavour, ensuring a truly delightful experience for tea and coffee enthusiasts worldwide.

Efficient Ozone-Based Sterilization

Harnessing advanced ozone generation, this system offers high-rate (>99%) sterilization and deodorization for tea leaves and coffee beans. The ozone, generated from pure oxygen at a density of 30 g/h, thoroughly eliminates microbes and odors while preserving product integrity. Its continuous-mode operation ensures consistent results and streamlined processing for large-scale operations.

User-Friendly PLC Automatic Control

The integrated PLC automatic control system simplifies operation for users, allowing for real-time monitoring and programming of all process parameters. This technology ensures precise ozone dosing, safety interlocks, and seamless adjustment for different processing loads, reducing manual intervention and optimizing efficiency.

Premium Construction and Safety Features

Constructed from high-quality stainless steel with a smooth, corrosion-resistant finish, the system is built for longevity and easy cleaning. Safety is enhanced by automatic overload protection, and the unit meets ISO certification standards. Its floor-mounted design, standard sizing, and low-noise operation (<60 dB) make installation and use suitable for various industrial environments.

FAQ's of Tea Leaf and Coffee Bean Processing with Ozone:

Q: How does the ozone processing system sterilize and deodorize tea leaves and coffee beans?

A: The system produces high-density ozone (30 g/h) from pure oxygen, which circulates around the tea leaves and coffee beans. Ozone's strong oxidizing properties break down and eliminate bacteria, mold, and odor-causing compounds, resulting in >99% sterilization and effective deodorization.Q: What are the benefits of using a PLC automatic control system in this processing machine?

A: The PLC automatic control system enables precise, programmable operations, real-time adjustment of processing parameters, and consistent ozone application. This minimizes manual intervention, improves safety, increases efficiency, and ensures reliable quality for each batch processed.Q: When is this ozone processing system best used in tea and coffee production?

A: This system is ideally implemented after initial cleaning but before packaging or storage. At this stage, ozone processing maximizes microbial reduction and deodorization, enhancing the shelf life, safety, and sensory qualities of tea leaves and coffee beans.Q: Where should the machine be installed, and what are the installation requirements?

A: The unit is floor-mounted and suitable for installation in processing facilities with a standard power supply (220 Volt, 50 Hz). It requires ambient temperatures between 5C-50C and should be placed in a well-ventilated area where pure oxygen supply is accessible to ensure optimal ozone generation.Q: What is the continuous operation process, and how does it improve productivity?

A: The system operates continuously, allowing for uninterrupted processing of up to 250 kg of product per hour. Raw tea leaves or coffee beans enter the machine, are exposed to controlled ozone treatment, and exit sanitized and deodorized, streamlining workflow and reducing downtime.Q: What safety measures are incorporated into the design of the processing system?

A: Key safety features include automatic overload protection to prevent equipment damage, and compliance with ISO standards. The system is designed for low noise operation and constructed with a corrosion-resistant finish for safer, long-term use in industrial settings.Q: What advantages does the stainless steel, corrosion-resistant construction offer for daily operation?

A: Stainless steel and the corrosion-resistant smooth finish ensure hygiene, durability, and ease of cleaning. This construction resists chemical degradation from ozone exposure and maintains structural integrity, supporting reliable, long-term industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

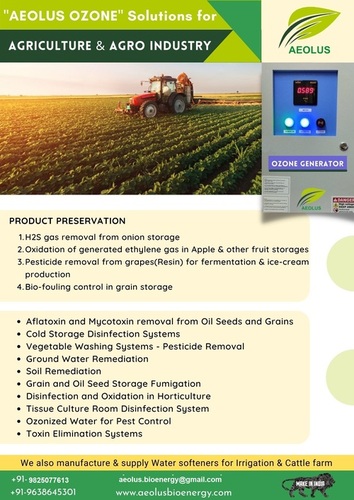

More Products in Food, Dairy Agri Aquaculture Industry Systems Category

Pesticide removal from Vegetables and Fruits with Ozone

Price 24000 INR / Plant

Minimum Order Quantity : 1 Plant

Voltage : 220440 Volt (v)

Frequency (MHz) : 50 Hertz (HZ)

Material : Ozone Generator with corona discharge technology

Warranty : 1 year conditional

Onion Storage and Preservation with Aeolus Ozone

Price 28000 INR / Plant

Minimum Order Quantity : 1 Plant

Voltage : 220440 Volt (v)

Frequency (MHz) : 50 Hertz (HZ)

Material : Ozone Generator with corona discharge technology

Warranty : 1 year

Dairy Ice-cream Food Beverage Industry Effluent Treatment XERODROP

Price 200000 INR / Plant

Minimum Order Quantity : 01 Plant

Voltage : 220440 V

Frequency (MHz) : 50 Hz

Material : Mild Steel

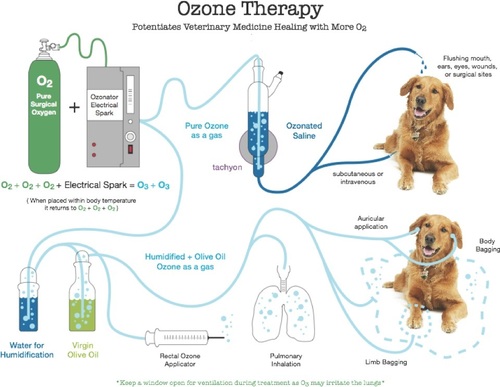

Veterinary Animal Health Care using Ozone by Aeolus

Minimum Order Quantity : 1 Plant

Voltage : 220440 Volt (v)

Frequency (MHz) : 50 Hertz (HZ)

Material : Ozone Generator with corona discharge technology

Warranty : 1 year conditional

Send Inquiry

Send Inquiry