Effluent Treatment Plant For Textiles Industries

Price 25000 INR/ Plant

Effluent Treatment Plant For Textiles Industries Specification

- Membrane Size

- Varied based on requirement

- Material

- High-grade Steel PVC Polypropylene

- Capacity

- Customizable

- Application

- Textile Industry Effluent Treatment

- Membrane Quantity

- Varied based on model

- Product Type

- Effluent Treatment Plant

- Technology

- Advanced Filtration Process (FIxe Cell Technology)

- Power Source

- Electric

- Operation Type

- Semi-Automatic/Automatic

- Pressure

- Standard Operational Pressure

- Dimension (L*W*H)

- Varied based on capacity and design

- Weight

- Varied based on size and capacity

- Color

- Varied (Commonly Green White Yellow)

- Warranty

- 1 Year Manufacturer Warranty

About Effluent Treatment Plant For Textiles Industries

Product details

| Feed Flow Rate | 50 m3/day,2000 m3/day,1000 m3/day,500 m3/day,100 m3/day |

| Water Source | Industrial Effluent |

| Capacity Inlet Flow Rate | 5000 m3/hour,2000 m3/hour,1000 m3/hour,500 m3/hour,100 m3/hour,10000 m3/hour |

| Installation Type | Prefabricated,Containerized Plug & Play |

| Treatment Stages | Preliminary Treatment,Disinfection,Tertiary Treatment,Secondary Treatment,Primary Treatment |

| Condition | New |

| Automation Grade | Semi-Automatic |

| Plant Type | Effluent Treatment Plant |

| Application | Textiles |

| Industry | Textiles |

Advanced Treatment for Textile Industry Effluent

Specifically designed for the textile sector, our ETP ensures efficient removal of contaminants, protecting the environment and supporting regulatory compliance. The use of FIxe Cell Technology enables superior filtration, while the material choices resist corrosion, providing durability against harsh effluents.

Customizable and Scalable Solutions

Each plant is tailored based on your operational requirements, including membrane size, dimension, and membrane quantity, ensuring optimal efficiency regardless of plant size or effluent volume. Both semi-automatic and fully automatic operation options are available to suit different facility management needs.

Reliable Performance with Manufacturer Warranty

We prioritize your confidence with a one-year manufacturer warranty, underlining the dependability of every ETP unit. Our systems are manufactured in India, adhering to rigorous quality standards, and are designed for long-term service with minimal maintenance demands.

FAQ's of Effluent Treatment Plant For Textiles Industries:

Q: How does the Effluent Treatment Plant for Textile Industries work?

A: Our ETP utilizes advanced FIxe Cell Technology, which involves a multi-stage filtration process to purify textile industry effluent. The plant systematically removes impurities and contaminants, making the output environmentally safe and compliant with industry standards.Q: What are the main benefits of using this ETP in textile industries?

A: The main benefits include effective removal of hazardous pollutants, customizable capacity for various plant sizes, compliance with environmental regulations, and reduced maintenance due to durable construction. Its reliable operation contributes to a cleaner production environment and a positive ecological impact.Q: When should I consider installing an effluent treatment plant for my textile facility?

A: Installing an ETP should be considered when your operation generates wastewater containing dyes, chemicals, or other pollutants. This is crucial for facilities aiming to meet legal discharge norms and enhance sustainability. If your business is expanding or facing stricter regulations, an upgrade may be necessary.Q: Where is the Effluent Treatment Plant typically installed within a textile production unit?

A: The plant is generally installed at a central location where effluent from various processes converges, such as near the main drainage or wastewater collection area. This facilitates efficient collection and treatment before discharge or reuse.Q: What is the standard process for customizing the ETP to my needs?

A: Customization starts with an assessment of your effluent volume, contaminant profile, and space constraints. Based on this, we recommend suitable membrane sizes, quantities, and dimensions that match your operational requirements. Our engineering team assists throughout the specification and installation process.Q: How is the ETP operated and what are its maintenance requirements?

A: The plant is available in both semi-automatic and automatic versions, allowing flexible operation according to your resources. Routine preventative maintenance, primarily checking membranes and key filtration components, helps ensure optimal performance and longevity.Q: What warranty and support can I expect with my ETP purchase?

A: Each ETP comes with a one-year manufacturer warranty covering defects in materials or workmanship. Technical support and guidance are available, ensuring prompt assistance for any issues that arise during operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemicals-Textile & Garment Industry Solutions Category

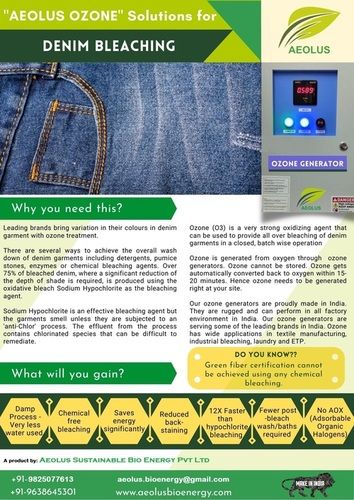

Denim and Textile Bleaching Ozone system

Price 45000 INR / Plant

Minimum Order Quantity : 1 Plant

Technology : Ozone Generator Technology

Dimension (L*W*H) : 1200 x 800 x 1500 mm

Weight : Approx. 120 kg

Membrane Size : 20 inches

Chemical Industry Effluent Treatment Systems

Price 200000 INR / Plant

Minimum Order Quantity : 1 , , Plant

Technology : Advanced filtration technology

Dimension (L*W*H) : Customizable

Weight : Varies depending on configuration

Membrane Size : Standard or customizable

Send Inquiry

Send Inquiry