Plastic Recycling Fumes Reduction System by Aeolus Ozone

Plastic Recycling Fumes Reduction System by Aeolus Ozone Specification

- Material

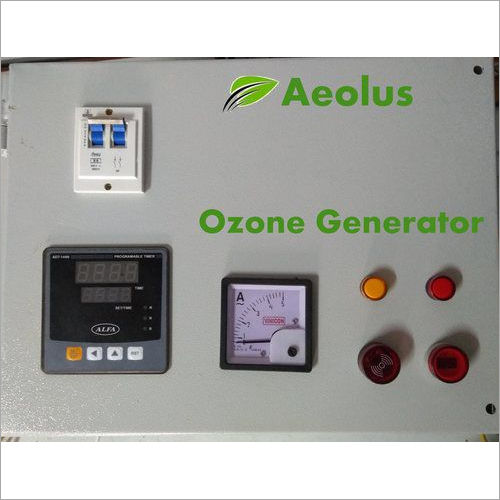

- Ozone generator based super oxidation system

- Automatic Grade

- Automatic

- Voltage

- 220-440 Volt (v)

- Warranty

- 1 year conditional

Plastic Recycling Fumes Reduction System by Aeolus Ozone Trade Information

- Minimum Order Quantity

- 1 Plant

- FOB Port

- Surat

- Supply Ability

- 10 Plants Per Month

- Delivery Time

- 4 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Middle East, Africa, Eastern Europe, South America, Asia

- Main Domestic Market

- Assam, Daman and Diu, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Uttarakhand, South India, Central India, Dadra and Nagar Haveli, East India, West India, Arunachal Pradesh, Bihar, Delhi, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Rajasthan, Sikkim, Tamil Nadu, Tripura, West Bengal, Kerala, Nagaland, Lakshadweep, Uttar Pradesh, Gujarat, North India, Telangana, Andhra Pradesh, Odisha, Chhattisgarh, All India

About Plastic Recycling Fumes Reduction System by Aeolus Ozone

Understanding the Problem Fumes in Plastic Recycling In the plastic recycling industry the reprocessing of plastics often involves melting extrusion and moulding releasing volatile organic compounds VOCs and other pollutants These emissions including hazardous fumes like dioxins furans and polyaromatic hydrocarbons PAHs pose serious health and environmental concerns Moreover they complicate compliance with stringent emission regulations

The Ozone Solution Ozone O3 a powerful oxidizing agent offers a multifaceted solution to combat fumes in plastic recycling Ozone's ability to oxidize organic compounds makes it highly effective in neutralizing harmful emissions rendering them harmless Here's how ozone can be applied

1Fume Oxidation Ozone can be introduced into the exhaust stream or process chamber where plastic recycling operations take place It reacts with VOCs and other pollutants breaking them down into less harmful byproducts

2Odour Control Ozone eliminates foul odours associated with plastic recycling improving working conditions and reducing complaints from surrounding communities

3Enhanced Safety By reducing harmful emissions ozone contributes to a safer working environment for personnel in recycling facilities

4Regulatory Compliance Ozone technology facilitates compliance with stringent emission regulations minimizing the risk of fines and legal issues

Commercial Benefits The adoption of ozone technology in plastic recycling brings several commercial advantages

1Cost Efficiency Ozone systems are cost-effective to install and maintain providing a favourable return on investment through improved compliance and reduced operational risks

2Enhanced Reputation Demonstrating a commitment to ecofriendly practices and emissions reduction can enhance a company's reputation and attract environmentally conscious clients

3Market Competitiveness Ozone equipped recycling facilities gain a competitive edge by showcasing their commitment to sustainability and compliance

4Environmental Responsibility Ozone adoption aligns with corporate social responsibility goals contributing to a greener and more sustainable image

Case Study A Sustainable Success Story Recycling a leading plastic recycling facility implemented ozone technology to combat emissions As a result

Emissions reduced by 40 complying with strict environmental regulations

Employee health and safety improved significantly

Client trust and contracts increased bolstering profitability

Conclusion Ozone technology has emerged as a transformative solution for the plastic recycling industry By efficiently reducing fumes neutralizing harmful emissions and enhancing sustainability it represents a crucial step toward greener and safer recycling practices Embracing ozone technology not only mitigates

Advanced Fume Neutralization

This system deploys ozone generator-based super oxidation to break down hazardous fumes generated during plastic recycling. By rapidly oxidizing chemical pollutants, it reduces air contamination and supports a cleaner workspace, benefiting both operators and the surrounding environment.

Automated Operation & Safety

Designed with automatic functionality, Aeolus Ozone's system streamlines integration into recycling plants. The automation enhances process reliability and safety, requiring minimal manual intervention and reducing operational risks associated with fume exposure.

Reliable Warranty & Indian Engineering

Manufactured in India, the system is backed by a conditional one-year warranty, assuring support and service for end-users. Its sturdy build and efficient performance make it a practical solution for recycling facilities seeking improved air quality control.

FAQ's of Plastic Recycling Fumes Reduction System by Aeolus Ozone:

Q: How does the Aeolus Ozone fume reduction system operate?

A: The system leverages an ozone generator-based super oxidation process. Ozone rapidly reacts with and decomposes toxic fumes from plastic recycling, neutralizing contaminants and improving air quality within the facility.Q: What are the main benefits of using this system in a recycling plant?

A: Key benefits include substantial reduction of harmful emission levels, enhanced worker safety, compliance with environmental standards, and the promotion of a healthier workplace atmosphere.Q: When should the system be implemented during the recycling process?

A: It is recommended to operate the system during active plastic recycling processes, especially when melting or chemical treatments are occurring, to ensure immediate and continuous fume mitigation.Q: Where can this fume reduction system be installed?

A: Ideal installation sites are plastic recycling facilities, manufacturing plants, or any operational area where plastic waste processing generates hazardous emissions.Q: What is the process for maintaining the Aeolus Ozone system?

A: Routine inspections and maintenance should be performed as per manufacturer guidelines, with attention to the ozone generator's function and automatic controls to sustain efficiency.Q: How does the automatic grade feature enhance the user experience?

A: Automatic operation simplifies system management, minimizing manual intervention and ensuring consistent fume reduction performance, thus improving plant productivity and user confidence.Q: Is there warranty support for technical issues?

A: Yes, the system comes with a conditional one-year warranty, covering manufacturing defects and select technical faults, supported by the manufacturer in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air disinfection deodorization pollution control Category

Home Air Purifier System by Aeolus

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Material : Mild Steel

Voltage : 220 V

Noise Level : 55 dB

Air Purifier System for Centralized AC and HVAC

Minimum Order Quantity : 1 Set

Automatic Grade : SemiAutomatic

Material : Highgrade galvanized steel & ABS plastic

Voltage : 220240 V

Noise Level : <45 dB

Foul Odour Control and Removal System by Aeolus ozone

Price 18000 INR / Plant

Minimum Order Quantity : 1 Plant

Automatic Grade : Automatic

Material : ozone generator

Voltage : 220 Volt (v)

Noise Level : Low

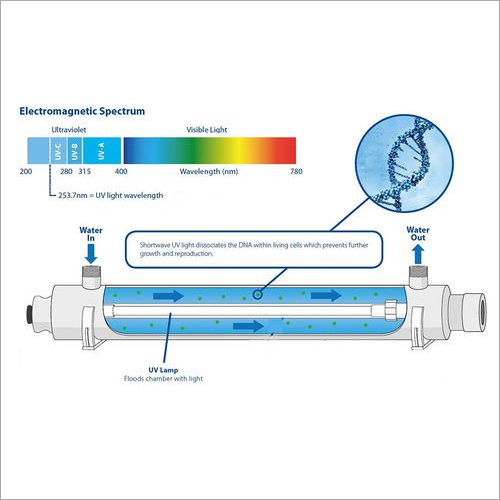

Ultra violet Disinfection Systems from Aeolus

Price 10000 INR

Minimum Order Quantity : 01 Plant

Automatic Grade : Automatic

Material : Stainless Steel

Voltage : 220 V

Noise Level : Low

Send Inquiry

Send Inquiry