Molasses Distillery Spent Wash Treatment Plant

Price 10000000 INR/ Plant

Molasses Distillery Spent Wash Treatment Plant Specification

- Color

- Green Yellow

- Voltage

- 220 Volt (v)

- Application

- Industrial

- Function

- ontainerized waste water treatment plant

- Material

- Stainless Steel

Molasses Distillery Spent Wash Treatment Plant Trade Information

- Minimum Order Quantity

- 1 , , Plant

- Payment Terms

- Cheque

- Supply Ability

- 10 Plants Per Year

- Delivery Time

- 4 -8 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- skid mounted or container mounted plants

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, , All India, South India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Delhi, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Lakshadweep, Uttar Pradesh, Gujarat, North India, Kerala, Central India, Odisha, Chhattisgarh

About Molasses Distillery Spent Wash Treatment Plant

Distilleries fermenting sugar cane molasses generate 6 -15 liters of waste water per liter of ethanol produced.

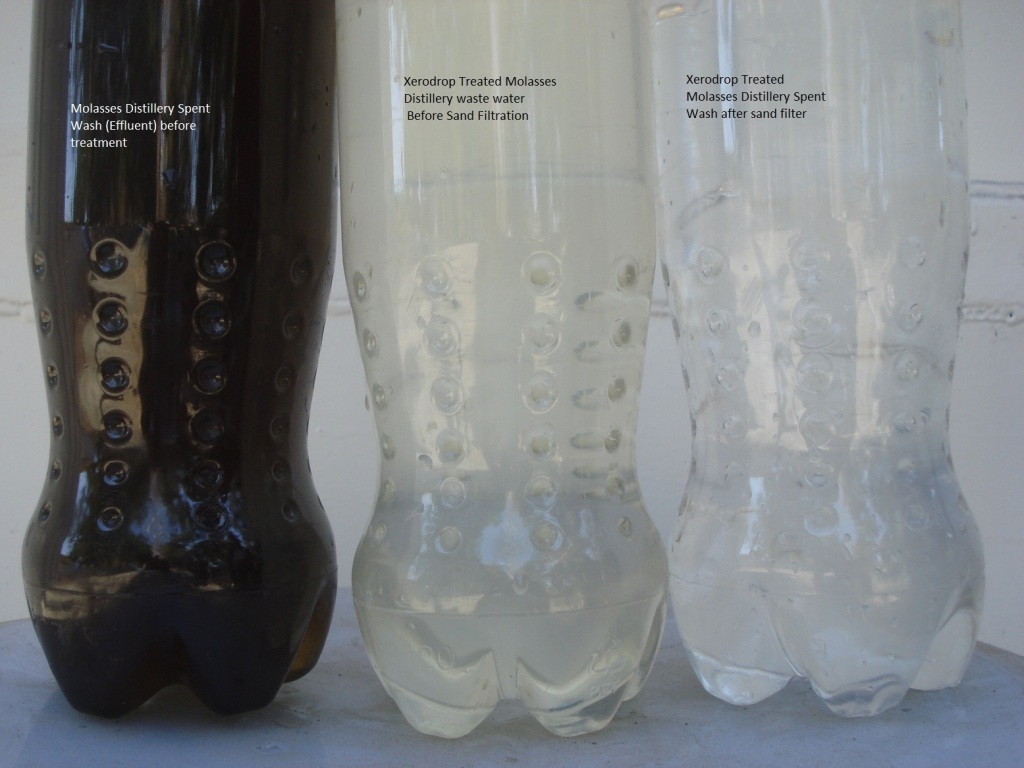

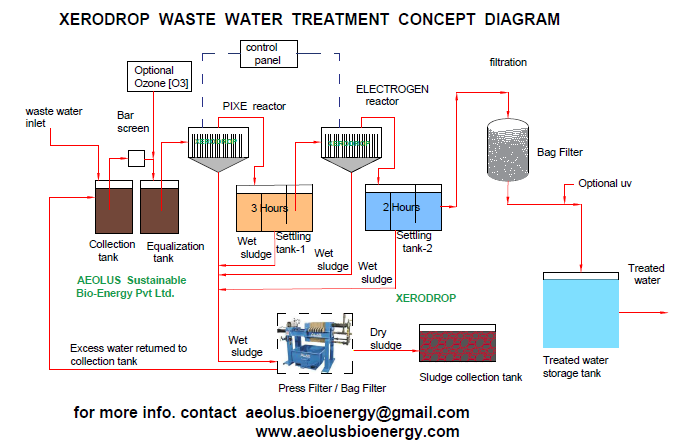

XERODROP is a method which is simple but very effective for treatment of many turbid water and waste waters. The technology is older than 100 years and is well documented internationally. However Aeolus has spent more than four years with untiring rigorous efforts implementing & restructuring the technology to treat highly recalcitrant effluents like distillery spent wash.

XERODROP-is a product with almost zero or negligible supervision to effectively treat highly recalcitrant effluents. Product has given amazing results with challenging waste waters of distillery spent wash (combined TOD values up to 2,20,000 ppm), tannery and paper mill effluents.

Molasses Distillery Spent Wash Treatment Plant is characterized by being:

- Highly acidic

- Very High BOD and COD

- High recalcitrant organics with dark colour and severe pungent smell.

- High concentration of recalcitrant COD persists even after both anaerobic and aerobic treatments.

- Melanoidins and polyphenolic complexes formed during fermentation is not easily decomposed by any conventional treatment

XERODROP DSW Distillery effluent treatment system treats the effluent without using any bacteria or chemicals and can achieve the stringent discharge norms. Contact us now!

Molasses Distillery Spent Wash Treatment Plant Details:

|

Feed Flow Rate |

50 m3/day, 100 m3/day, 500 m3/day |

|

Usage/Application |

Waste water treatment & hazardous effluent treatment plant |

|

Water Source |

Commercial Waste Water, Municipal Sewage, Industrial Effluent, Hazardous Effluents |

|

Treatment Technique |

Electro-chemistry and advanced oxidation process |

|

Type |

Waste Water Treatment |

|

Condition |

New |

|

Treated Water Quality |

As per CPCB discharge Norms |

|

Treatment Stages |

Tertiary Treatment, Primary Treatment, Electro-Coagulation,Electro Oxidation,Electro-Floatation,Ozone,UV, Secondary Treatment, Disinfection |

|

Installation Type |

Prefabricated, Containerized Plug & Play |

|

Features |

Containerized waste water treatment plant |

|

Overall Dimensions |

20 ft and 40 ft standard cargo containers |

|

Manufacturing Lead Time |

8-12 weeks |

|

Material of Construction |

FRP, MS |

|

Control Module |

Control Module Available |

|

Filtration System |

Micron filters |

|

Industry |

Distillery |

|

Plant Type |

Wastewater Treatment Plant |

|

Application |

sewage, Effluent and hazardous waste water treatment |

Efficient Containerized Treatment

This spent wash treatment plant delivers a compact and containerized solution for industrial wastewater. Its modular design supports easy transportation, installation, and scalability, making it ideal for diverse distillery operations across India.

High-Quality Stainless Steel Construction

The plant features corrosion-resistant stainless steel materials, ensuring structural integrity and longevity even under harsh operating conditions. This makes maintenance straightforward and enhances uptime for users.

Eco-Friendly Wastewater Management

By using advanced treatment processes, the unit reduces environmental impact, enabling safe and compliant wastewater discharge. These benefits align with local regulations, supporting sustainable industrial practices.

FAQ's of Molasses Distillery Spent Wash Treatment Plant:

Q: How does the Molasses Distillery Spent Wash Treatment Plant function?

A: The plant utilizes a containerized system to treat spent wash from distilleries. Integrated technologies filter and process effluent, ensuring contaminants are removed and water is safely discharged or repurposed.Q: What is the main process involved in treating spent wash using this plant?

A: The process begins with the collection of spent wash, followed by filtration, chemical treatment, and biological processing within stainless steel tanks. The treated water meets environmental standards for industrial discharge or reuse.Q: When should manufacturers install a Molasses Distillery Spent Wash Treatment Plant?

A: Manufacturers should consider installing the plant whenever they need to manage high volumes of spent wash in compliance with regulatory norms, particularly during increased production or facility expansion.Q: Where is this treatment plant commonly used?

A: This system is widely implemented in industrial distilleries across India, especially where eco-friendly spent wash management is a legal or operational requirement.Q: How is the plant operated and maintained?

A: The plant operates with a 220 Volt power supply and features stainless steel construction for durability. Routine maintenance includes cleaning, inspection, and occasional parts replacement, which is facilitated by its modular, containerized design.Q: What are the benefits of using this treatment plant?

A: Benefits include reduced environmental impact, regulatory compliance, efficient water recycling, and improved operational safety. It also saves costs associated with effluent management in industrial settings.Q: Can the treated water from this plant be used for other industrial processes?

A: Yes, the treated water can be repurposed for processes such as cooling, cleaning, or irrigation, depending on the level of purification achieved and specific industry needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Distillery Spent Wash Treatment Category

Distillery Spent Wash Treatment

Price 5000000 INR

Minimum Order Quantity : 1 Plant

Color : Industrial Grey

Product Type : Distillery Spent Wash Treatment System

Dimension (L*W*H) : Customized as per requirement

Membrane Size : Standard/Customized

Send Inquiry

Send Inquiry