Electro Chlorination System

Price 125000.00 INR/ Plant

Electro Chlorination System Specification

- Usage & Applications

- Drinking water disinfection, Cooling Towers, Industrial process water, Wastewater treatment, Swimming pools

- Flow Rate

- Customizable (typically 500 - 20000 LPH)

- Power Consumption

- 1.5 to 7 kWh / kg of chlorine generated

- Water in conductivity

- Up to 1500 S/cm

- Technology

- Electrolysis Based Salt Water Chlorination

- Water Out Conductivity

- Less than 2 S/cm

- Efficiency (%)

- Up to 98%

- Pump Type

- Dosing Pump

- Feature

- Corrosion Proof, Energy Efficient, Compact Design

- Noise Level

- Less than 60 dB

- Recycle Rate

- Up to 90% (Depending on application and design)

- Ph Level

- Adjustable, typically 6.5-8.0

- Frequency

- 50/60 Hz

- Volume

- Customizable as per system requirement

- Water Source

- Municipal, Borewell, or Sea Water

- Product Type

- Electro Chlorination System

- Drive Type

- Direct Drive

- Automatic Grade

- Automatic

- Voltage

- 380-440 V AC, 3 Phase

- Material

- FRP, PVC, SS316, Titanium for Electrodes

- Purity Level

- 0.6% to 1% NaOCl solution (Sodium Hypochlorite)

- Power Source

- Electric

- Filter Type

- Pre-filtration cartridge/Bag filter

- Capacity

- 500 LPH to 50000 LPH (customized)

- Installation Type

- Skid Mounted, Containerized

- Control Panel

- PLC-based digital interface

- Inlet Pressure

- 0.2 - 0.4 Mpa

- Chlorine Output

- 0.8% solution (NaOCl)

- Service Life

- >7 years (for electrodes)

- Operating Temperature

- 5°C to 50°C

- Maintenance

- Low, periodic inspection recommended

- Leakage Detection

- Integrated sensor alarm

- Electrode Type

- Titanium coated with MMO

- Safety Features

- Overload & short circuit protection

- Ambient Humidity

- Up to 95% RH

Electro Chlorination System Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 100 Sets, Set Per Month

- Delivery Time

- 1-6 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, Uttarakhand, Daman and Diu, , South India, East India, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Jammu and Kashmir, Jharkhand, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Lakshadweep, Uttar Pradesh, Haryana, Karnataka, North India, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

About Electro Chlorination System

By adhering to all the prevailing quality norms of the industry, we have become a pioneer manufacturer and trader of a wide gamut of Electro Chlorination System. To design and develop these systems we are backed by a team of highly competent and dexterous team of professionals who go out of the box to design these systems. Available at industry leading price, our range of Electro Chlorination System is highly appreciate for its accurate result.

The Robust Technology

- On site hypochlorite generator

- Works on principle of Electrolysis

- Uses patented electrodes

- Design developed on 30 years indigenous research by Internationally renowned Scientist

- Holds hundreds of satisfied customers around the globe

Application & Uses

- Hospital Floor & Drinking water disinfection

- Drinking water disinfection

- Swimming pool Chlorination

- Village water treatment

- Drinking water and floor disinfection for Schools, Airport, Hospital, Community center, baby sitting, play house, office, home, hotel, restaurants, banquet halls, village and urban water treatment plants

- Waste water treatment plants tertiary treatment & disinfection

- Dairy & food industry raw water treatment

- Laundry

Availability: Electro-chlorinators are available in various sizes and concentration of Hypo chlorite generation

Product Details:

| Fuel Type | Natural Gas, Diesel |

| Application | Hospital |

| Body material | Metal |

| Concentration | 7000 to 8000 ppm max in a 8 hour batch |

Advanced Electrode Technology

Equipped with titanium electrodes coated in MMO, this electrochlorinator ensures high chemical resistance and exceptional longevity, exceeding seven years of service life. The electrode design supports a stable chlorine output while maintaining minimal maintenance requirements and consistent efficiency, ensuring reliable operation even in demanding conditions.

User-Friendly Operation and Digital Controls

The system features a PLC-based digital control panel, offering intuitive, precise operation and real-time monitoring. Integrated safety features, including automatic leakage detection and overload protection, maximize operational safety. Users benefit from a streamlined maintenance schedule, with periodic inspections recommended for optimal performance.

Flexible, Energy-Efficient Water Disinfection

This customizable electro chlorination solution caters to various flow rates and volumes, supporting municipal, borewell, or sea water. With power consumption between 1.5 and 7 kWh per kg of chlorine generated and up to 98% operational efficiency, it delivers high-purity sodium hypochlorite (0.61%) economically and with a compact footprint.

FAQs of Electro Chlorination System:

Q: How does the electro chlorination system generate sodium hypochlorite on-site?

A: This system produces sodium hypochlorite (NaOCl) through salt-water electrolysis. Brine, prepared from water and salt, passes through titanium electrodes coated with MMO inside the electrolysis cell, generating a 0.8% NaOCl solution for disinfection.Q: What safety features are included to ensure reliable operation?

A: The electro chlorination system is equipped with several safety features, including an integrated leakage detection sensor with alarm, overload and short circuit protection, as well as automatic shutdown protocols for hazard prevention.Q: When and how often should maintenance or inspection be carried out?

A: Although the system is designed for low maintenance, regular periodic inspections are recommended to ensure optimal performance. Frequency may depend on operating environment and usage intensity, but annual professional maintenance is advisable.Q: Where can this electro chlorination system be installed and used?

A: Its robust and corrosion-proof construction allows installation in diverse environmentsskid-mounted or containerizedfor drinking water plants, industrial process water, cooling towers, wastewater treatment, and swimming pools. It accepts municipal, borewell, or sea water as input.Q: What benefits does the PLC digital control panel provide users?

A: The PLC-based interface simplifies operation, allowing users to monitor real-time system parameters, adjust settings, and receive alerts for potential issues such as leaks or electrical faults, thus enhancing both convenience and safety.Q: How is the systems chlorine output and water conductivity controlled?

A: Chlorine output ranges from 0.6% to 1% NaOCl solution. Incoming water conductivity is managed up to 1500 S/cm, while output water conductivity is maintained below 2 S/cm, ensuring high-purity disinfectant compatible with sensitive applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lake, Pond, River Cleaning Category

Disc Filter

Price 4000.00 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : FRP / Polypropylene / Stainless Steel

Voltage : 220240 V

Recycle Rate : Up to 99%

Automatic Grade : Other, Automatic

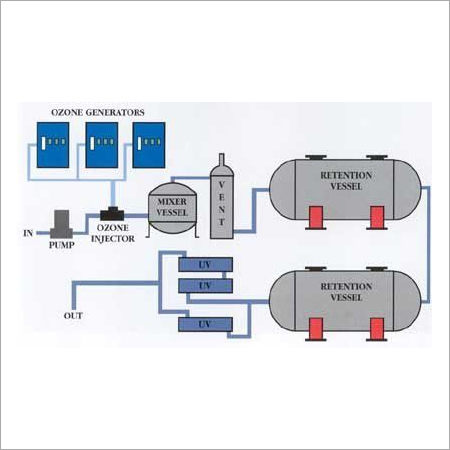

UV disinfection systems from Aeolus

Price 25000 INR / Plant

Minimum Order Quantity : 01 Plant

Material : Stainless Steel

Voltage : 220V

Recycle Rate : 100%

Automatic Grade : Other, Automatic

Water disinfection system

Price 18000 INR / Set

Minimum Order Quantity : 1 Set

Material : SS 304 SS 316

Voltage : 230 V AC Ampere (amp)

Recycle Rate : as per your need

Automatic Grade : Full Automatic

Lake Pond Water Body water quality management with Aeolus Ozone

Price 50000.00 INR / Plant

Minimum Order Quantity : 4 Plants

Material : Ozone generator with corona discharge

Voltage : 220440 Volt (v)

Recycle Rate : 95%

Automatic Grade : Full Automatic

Send Inquiry

Send Inquiry