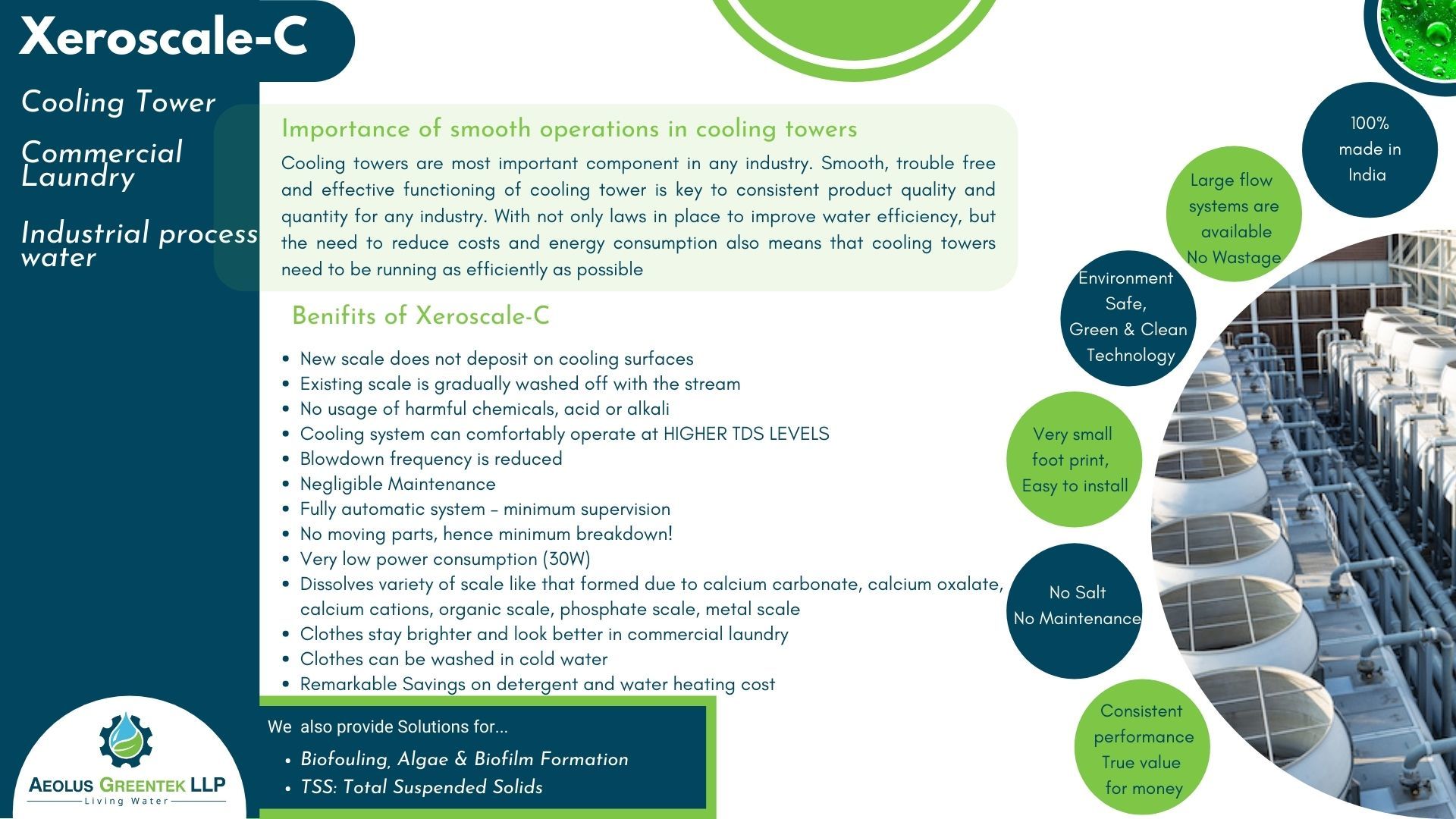

Cooling Tower Water Treatment Systems

Product Details:

- Purity Level ChemicalFree

- Voltage 220440 Volt (v)

- Material Mild Steel

- Power Source Mains Electricity

- Automatic Grade Full Automatic

- Click to View more

Cooling Tower Water Treatment Systems Price And Quantity

- 1 Plant

- 45000 INR/Plant

- 25000.00 - 250000.00 INR/Plant

Cooling Tower Water Treatment Systems Product Specifications

- 220440 Volt (v)

- ChemicalFree

- Full Automatic

- Mains Electricity

- Mild Steel

Cooling Tower Water Treatment Systems Trade Information

- Cash Advance (CA), Cheque, Cash in Advance (CID)

- 10 Plant Per Month

- 4 Week

- Yes

- Contact us for information regarding our sample policy

- Transportable package

- Australia, North America, Central America, Eastern Europe, Africa, Asia, South America, Western Europe, Middle East

- Gujarat, All India, Chhattisgarh, Maharashtra, Sikkim, West India, North India, South India, Central India, Karnataka, Kerala, Assam, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Jammu and Kashmir, Madhya Pradesh, East India, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Daman and Diu, Delhi, Tamil Nadu, Pondicherry, Uttar Pradesh, Chandigarh, Goa, Jharkhand, Odisha, Punjab, Nagaland, Tripura, Haryana, Himachal Pradesh, Rajasthan, Telangana, Uttarakhand, West Bengal

- CE on demand

Product Description

based water disinfection

Low concentration sodium hypochlorite a powerful disinfectant is generated in-line consuming common salt NaCl available in water. Long life Titanium electrodes with MMO coating are used with DC current. System is designed as pipe spool piece with auto cleaning feature. No daily maintenance.

3. based water disinfection

7000-8000 ppm sodium hypochlorite is generated on site using common salt and fresh water. Generated hypochlorite is then dosed proportionately to maintain disinfection. No dependency on third party suppliers and keeping stock of perishable hypochlorite.

4. based water disinfection

Hypochlorous is more powerful oxidant even better than hypochlorite. Hypochlorous is geneMild Steel

rated on site using common salt and water in process similar to hypochlorite. Generated hypochlorous is dosed in recirculation using appropriate dosing pumps

5. based water oxidation and disinfection

Ozone most powerful oxidizing agent known much more powerful as compared to chlorine; can be generated on site using ambient air or oxygen as feed. Generated ozone is purged into recirculation line. Ozone readily kills algae and most micro-organisms and thereby controls bio-fouling, bio-film without generating any hazardous chemical residue. More the DO level in sump better the bio-film control!

6. for in-sump and on-fin disinfection

UV zapper is a water & weatherproof UV light which can be installed as submerged in sump or between the fins. Strong UV radiation generated will control bio-fouling without any chemical.

7. for recirculation based disinfection

We have a unique UV system design, wherein water does not come in direct contact with UV lamps. There are no fragile quartz tubes also. Entire electrical system is galvanically isolated. Absolutely Safe!

8. in sump

Our specially designed electro-oxidation and electro-floatation system oxidizes sump water and also reduces suspended solids in sump water. Flocs formed by electro-floatation is drained in blow down.

9.

Graphene is the new generation nano particle based water purification and filtration system. Desalination is the best property of graphene. Organic compounds are also eliminated with graphene clad membranes.

11. Chlorine dioxide is another safe chlorine compound which renders cooling tower free of bio-fouling. Chlorine dioxide is available in tablet and powder form.

Total Suspended Solids TSS

1. for side stream flow

Electro-coagulation is proven technology for TSS control in cooling system. Optimum coagulant is generated from electrodes. Suspended particles are precipitated & filtered out without chemical addition. Certain amount of calcium and magnesium compounds are also precipitated.

2. for side stream

Our vertical bag filters require very small space for fast and effective filtration for side stream. Low to moderate pressure required for micron bag filtration makes it affordable and effective.

3. for side stream

We have unique non-rigid PTFE hollow fibre membrane design, which can be thoroughly cleaned. PTFE ensure no clogging or scale deposition on membranes. Ultra-filtration ensures best quality water management in cooling water system.

4. for side stream

Graphene clad membranes as mentioned above not just reduces TSS but also ensure elimination of organic compounds and offers best health for cooling system with minimum maintenance.

5. filtration systems

Glass beads are new alternative to conventional quartz sand, Most attractive feature of glass bead as filter media is micro-fine filtration, no bio-fouling, 30% less back wash, minimum 25 years life for filter media. Existing quartz sand filters can be replenished with new glass bead media. Glass bead also exhibit adsorption like carbon filter to some extent.

6. We also offer conventional sand filter system with manual multi-port valve for side stream filtration.

Cooling systems can comfortably operate at HIGHER TDS LEVELS.

Thanks! We await to hear from you!

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free