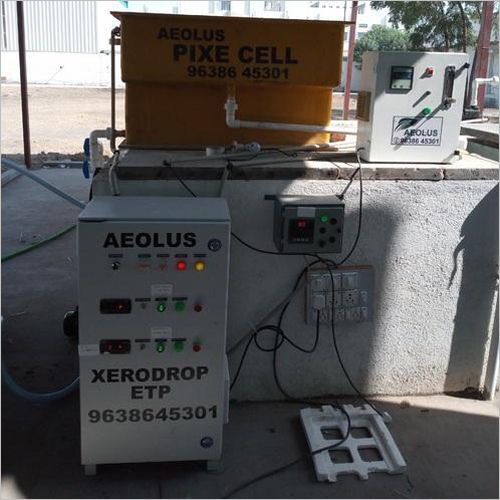

Bio-fouling Control for Cooling Towers Without Using Chemicals By Aeolus

Price 45000 INR/ Piece

Bio-fouling Control for Cooling Towers Without Using Chemicals By Aeolus Specification

- Frequency

- 50/60 Hz

- Ph Level

- Neutral maintenance, 6.5-8.5

- Usage & Applications

- Industrial & commercial cooling towers, HVAC, process cooling

- Recycle Rate

- Up to 100% continuous recirculation

- Flow Rate

- Up to 100 m/hr

- Water Out Conductivity

- Customizable as per requirement

- Power Consumption

- 2-6 kW/hr (depends on capacity)

- Efficiency (%)

- Above 90%

- Noise Level

- < 70 dB

- Feature

- Chemical-free, eco-friendly, zero-downtime operation

- Water in conductivity

- Variable, based on source and process

- Pump Type

- Centrifugal/Multistage

- Technology

- Physical water treatment via ultrasonic/cavitation

- Water Source

- Industrial and commercial cooling tower water

- Drive Type

- Direct

- Power Source

- Electric

- Product Type

- Non-chemical Bio-Fouling Control Unit

- Automatic Grade

- Fully Automatic

- Purity Level

- Up to 99% bio-fouling reduction

- Voltage

- 220-240 V AC, 50/60 Hz

- Volume

- 1 m to 100 m/hr

- Material

- Stainless Steel 304/316, corrosion-resistant polymers

- Filter Type

- Integrated mesh and pre-filter

- Capacity

- Designed as per site & tower size

- Installation Type

- Skid mounted or standalone

- Alarm/Notification

- Integrated malfunction/maintenance alarm

- Dimensions

- Customized according to tower/site

- Bypass Requirement

- No bypass needed

- Control Interface

- Digital control panel with status indication

- Maintenance Requirement

- Minimal, quarterly inspection recommended

- Operating Temperature Range

- 5°C to 55°C

- Environment Compliance

- Meets RoHS, REACH directives

- Mounting

- Floor/wall/skid mount

- Safety Standard

- CE certified (where applicable)

Bio-fouling Control for Cooling Towers Without Using Chemicals By Aeolus Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 2 Days

About Bio-fouling Control for Cooling Towers Without Using Chemicals By Aeolus

Product details

| Capacity Inlet Flow Rate | All capacities 1 M3 onwards |

| Usage/Application | cooling tower water treatment and biofouling control |

| Water Source | cooling tower water |

| Treatment Stages | Secondary Treatment,Primary Treatment |

| Capacity | all capacities |

| Treatment Technique | Advance Oxidation Process |

| Industry | All industries |

| Delivery Location | Pan India |

Advanced Chemical-Free Bio-fouling Control

Employing physical water treatment through ultrasonic and cavitation effects, Aeolus eliminates the need for chemicals, providing safe and sustainable fouling control. The solution enhances cooling efficiency and minimizes health and environmental risks without operational downtime.

Minimal Maintenance and Seamless Operation

This system features a fully automatic interface and integrated maintenance alarms, ensuring reliable operation with only quarterly inspections recommended. Direct drive and centrifugal/multistage pumps enable durable, efficient performance, while flexible mounting options optimize space utilization.

Tailored to Your Cooling Tower Needs

With customizable dimensions, variable flow capacities, and adaptable water conductivity settings, Aeolus delivers solutions suited to diverse industrial and commercial applications. The robust design ensures compatibility with varied site requirements and water conditions.

FAQs of Bio-fouling Control for Cooling Towers Without Using Chemicals By Aeolus:

Q: How does Aeolus system control bio-fouling in cooling towers without chemicals?

A: Aeolus employs ultrasonic and cavitation technologies to physically disrupt biofilm and inhibit fouling organisms growth. This process effectively controls bio-fouling and maintains operational efficiency entirely without chemicals.Q: What maintenance is required for the Aeolus bio-fouling control system?

A: The system is designed for minimal maintenance, with only a quarterly inspection recommended. It also features an integrated alarm to notify operators of any malfunction or maintenance needs, minimizing unplanned downtime.Q: When should the system be installed or inspected for best performance?

A: Installation can be performed during commissioning or as a retrofit without requiring any bypass. Quarterly inspections are recommended to ensure consistent operation and optimal performance.Q: Where can the Aeolus system be used?

A: This technology is suitable for industrial and commercial cooling towers where effective, chemical-free fouling control is needed, including HVAC and process cooling applications. Its modular construction allows for floor, wall, or skid mounting depending on site layout.Q: What is the process behind Aeolus physical water treatment technology?

A: By leveraging ultrasonic/cavitation mechanisms, the system disrupts microorganism colonies and biofilm formation, enhancing water purity and reducing fouling without introducing chemicals into the water.Q: How does the system benefit users compared to traditional chemical dosing?

A: Users benefit from a safer environment, reduced chemical handling, lower operational costs, continuous uptime, regulatory compliance, and ecologically responsible operation, all while achieving over 90% efficiency in foulant reduction.Q: Is the system compatible with all types of cooling tower water sources?

A: Yes, the Aeolus system is adaptable to variable water conductivity and can be tailored to suit a range of industrial and commercial water sources, ensuring effective treatment regardless of source conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Advanced Oxidation Processes (AOP) Category

Advanced Oxidation Process ETP-STP - XERODROP AOP

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Low Sludge Generation, No Chemical Dosing, Compact Design, Low Maintenance

Noise Level : Below 70 dB

Installation Type : Other , Containerized/Skid Mounted

Efficiency (%) : > 95%

Modification of Existing ETP-STP with XERODROP AOP

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Advanced Oxidation Process (AOP), Quick Installation, Compact Footprint

Noise Level : < 60 dB

Installation Type : Other , Modular/Containerized

Efficiency (%) : up to 98%

Evaporator Condensate Treatment with AOP

Price 150000 INR / Unit

Minimum Order Quantity : 01 Plant

Feature : AOP Technology for Advanced Purification

Noise Level : < 70 dB

Installation Type : Other , Skid Mounted

Efficiency (%) : 98%

Send Inquiry

Send Inquiry