Aflatoxin Mycotoxin removal system for food grains and oil seeds

Price 27000 INR/ Plant

Aflatoxin Mycotoxin removal system for food grains and oil seeds Specification

- Voltage

- 220 V

- Product Type

- Aflatoxin Mycotoxin Removal System

- Material

- Stainless Steel

- Capacity

- 250 kg/hr

- Ozone Density

- 8-15 mg/L

- Sterilizer Rate

- 99.99%

- Power

- 2.8 KW

- Frequency (MHz)

- 50 Hz

- Size

- Industrial Standard

- Weight

- 180 kg

- Dimension (L*W*H)

- 1200*650*1450 mm

- Air Source

- High-Efficiency Ozone Generator

- Application

- Food Grains and Oil Seeds

- Noise Level

- 60 dB

- Installation Type

- Floor Standing

- Decontamination Technology

- Ozone-Based Detoxification

- Temperature Range

- -10C to 60C

- Control System

- PLC Controlled

- Service Life

- 10 Years

- Compliance

- ISO 9001 Certified

- Operation Mode

- Automatic

- Safety Features

- Leakage Detector, Emergency Stop

Aflatoxin Mycotoxin removal system for food grains and oil seeds Trade Information

- Minimum Order Quantity

- 1 Plant

- Supply Ability

- 15 Plants Per Month

- Delivery Time

- 5 Week

- Sample Policy

- Contact us for information regarding our sample policy

About Aflatoxin Mycotoxin removal system for food grains and oil seeds

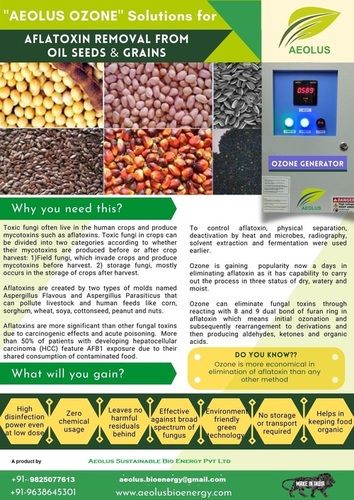

Ozone application in Aflatoxin Reduction - destruction: Ozone is approved under GRAS (Generally Recognized as Safe) by US FDA, when used on raw agricultural commodities, since 2001. This use of Ozone is consistent with section 201(q)(1)(B)(1) of the Federal Food, Drug and Cosmetic Act since 2001.

Aflatoxins are resistant against Gamma radiation.

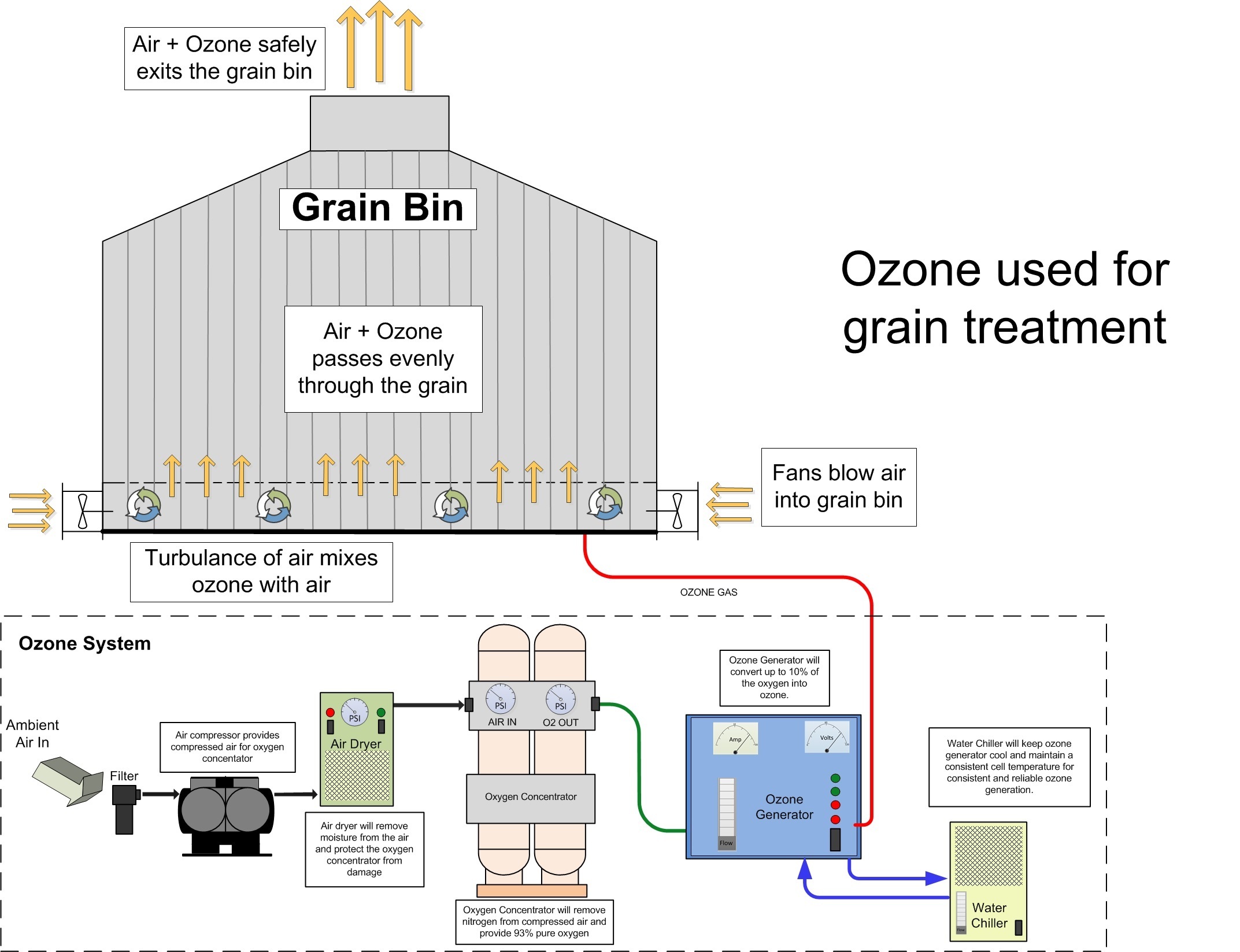

Ozone is an unstable gas with a pungent, characteristic odor. It is producedin situ from oxygen either by ultraviolet irradiation of air or by passinga high voltage discharge through air. It is a potent oxidizing agent thatdecomposes at ambient temperature to molecular oxygen.

Ozone is approximately 3000 times powerful then chlorine in killing bacteria and other microbes. Even at low concentration it has high microbe killing power and Ozone does not leave behind any residues. Ozone destructs mycotoxins like Aflatoxin using Creegie Mechanism.

Aeolus has several installations to reduce Aflatoxins from peanuts andother food grains. Ozone also fumigates the food grain and oil seeds for longterm storage.

Please share your oil seed and food grain processing capacity andprocess details. We can offer you the right solution for removing Aflatoxinsand Mycotoxins from it with our Ozone Generators and their applicationmechanisms.

Ozone-Based Detoxification for Safe Food Processing

By leveraging ozone as a powerful oxidizer, this system efficiently eliminates harmful aflatoxins and mycotoxins from food grains and oil seeds. The ozone generator creates a controlled environment that breaks down contaminants without leaving toxic residues, ensuring your products are both safe and market-ready. Automated controls and safety features contribute to simple, hands-off operation, minimizing risk and maximizing reliability.

Robust Design and Smart Controls

Manufactured in India and crafted from premium stainless steel, the mycotoxin removal unit withstands demanding industrial environments. The PLC control system allows for easy monitoring and adjustment, while safety mechanisms such as leakage detection and emergency stops ensure fail-safe operation. With up to 10 years of service life and capacity for 250 kg/hr, it's engineered for high-volume, continuous processing.

FAQ's of Aflatoxin Mycotoxin removal system for food grains and oil seeds:

Q: How does the Aflatoxin Mycotoxin Removal System ensure safe detoxification of food grains and oil seeds?

A: The system uses advanced ozone-based detoxification technology, which effectively oxidizes and decomposes harmful aflatoxins and mycotoxins, achieving a sterilization rate of 99.99%. Ozone treatment safely destroys contaminants without leaving chemical residues, preserving product quality.Q: What types of food products can be treated with this system?

A: This system is designed for the decontamination of a wide range of food grains and oil seeds, including but not limited to wheat, maize, rice, peanuts, and sunflower seeds, making it a versatile solution for various agro-industrial applications.Q: When is the optimal time to use the ozone detoxification system during processing?

A: For best results, use the system on cleaned and pre-processed grains or seeds before packaging or storage. This ensures that the decontamination process targets mycotoxins effectively while maintaining product integrity.Q: Where can this floor-standing system be installed in a facility?

A: The machine is designed for convenient floor-standing installation in processing plants, warehouses, or food safety labs. Its industrial standard size ensures it fits seamlessly within existing production lines without major modifications.Q: What process does the system use to remove aflatoxins?

A: Ozone generated at a density of 8-15 mg/L is introduced into the chamber containing the grains or seeds. The ozone circulates and reacts with the toxins, breaking them down safely while the PLC control system oversees cycle parameters for optimal performance.Q: How does the automatic control system facilitate usage and safety?

A: The integrated PLC (Programmable Logic Controller) allows automated operation, precise monitoring, and adjustment of process variables. Safety features such as a leakage detector and emergency stop provide additional protection to operators and facilities.Q: What are the key benefits of using this ozone-based mycotoxin removal system?

A: Key benefits include high decontamination efficiency (99.99%), compliance with ISO 9001 standards, chemical-free operation, low noise emission ( 60 dB), long service life (10 years), and the processing of up to 250 kg/hr-all contributing to safer, more reliable food production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food, Dairy Agri Aquaculture Industry Systems Category

Pesticide removal from Vegetables and Fruits with Ozone

Price 24000 INR / Plant

Minimum Order Quantity : 1 Plant

Material : Ozone Generator with corona discharge technology

Warranty : 1 year conditional

Product Type : Advance Oxidation & disinfection system based on Ozone

Frequency (MHz) : 50 Hertz (HZ)

Horticulture Ozone Generator by Aeolus

Price 27000 INR / Plant

Minimum Order Quantity : 1 Plant

Material : Ozone Generator with corona discharge technology

Warranty : 1 year

Product Type : Advance Oxidation & disinfection system based on Ozone

Frequency (MHz) : 50 Hertz (HZ)

Aquaculture Water Quality Management by Aeolus Ozone

Price 27000 INR / Plant

Minimum Order Quantity : 1 Plant

Material : Ozone Generator with corona discharge technology

Warranty : 1 year conditional

Product Type : Advance Oxidation & disinfection system based on Ozone

Frequency (MHz) : 50 Hertz (HZ)

Onion Storage and Preservation with Aeolus Ozone

Price 28000 INR / Plant

Minimum Order Quantity : 1 Plant

Material : Ozone Generator with corona discharge technology

Warranty : 1 year

Product Type : Advance Oxidation & disinfection system based on Ozone

Frequency (MHz) : 50 Hertz (HZ)

Send Inquiry

Send Inquiry