Pharmaceutical Chemical Industry Effluent Treatment Plants from Aeolus

Price 1000000.00 INR/ Plant

Pharmaceutical Chemical Industry Effluent Treatment Plants from Aeolus Specification

- Shape

- Rectangular or cylindrical as per site conditions

- Power Source

- Electric

- Capacity

- Design specific, available in various capacities

- Weight

- As per capacity and design

- Frequency

- 50/60 Hz

- Type

- Effluent Treatment Plant

- Properties

- Robust construction, corrosion resistance, high efficiency, long service life

- Feature

- Non biological effluent treatment, eco-friendly process, high removal efficiency

- Usage

- For treatment of wastewater/effluent from pharmaceutical and chemical industries

- Material

- Mild steel with FRP lining or Stainless Steel

- Recommended For

- Pharmaceutical, Chemical industries

- Dimension (L*W*H)

- Customized as per requirement

- Electricity Consumption

- Low power consumption

- Color

- Industrial Gray / Blue

- Automation Grade

- Semi Automatic

- Features

- Can handle high TDS and COD/BOD loads, low maintenance, compact footprint

- Discharge Compliance

- CPCB & SPCB discharge standards

- Effluent Quality Achievable

- Meets stringent discharge norms for pharmaceutical sector

- Treatment Process

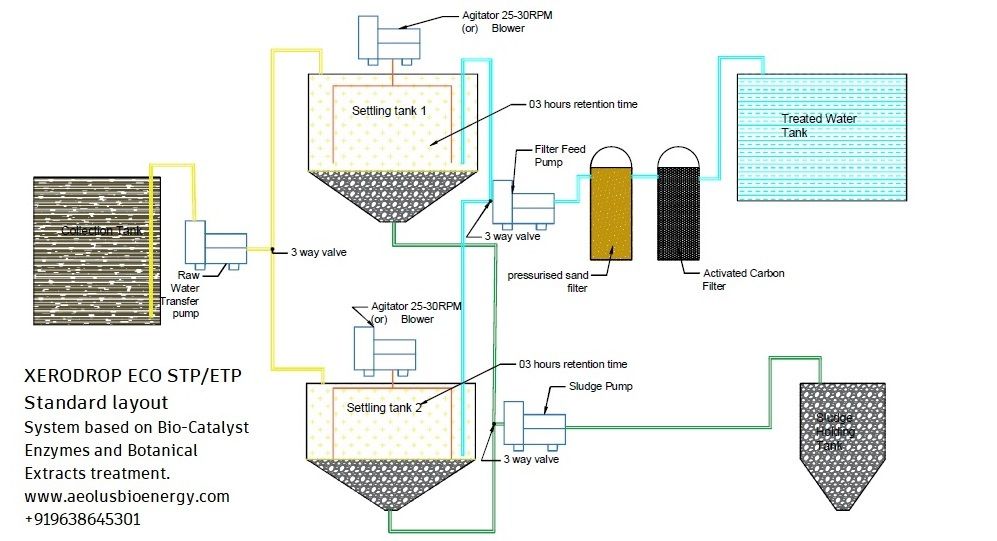

- Advanced electrochemical oxidation (XERODROP)

- Control Panel

- User-friendly, equipped with safety interlocks

- Installation

- Turnkey project supply with on-site installation

- Operation & Maintenance

- Minimal, does not require skilled labor

- Plant Life Span

- 10+ years with proper maintenance

- Treated Water Reuse

- Suitable for gardening, cooling towers, or other non-potable applications

- Service Support

- Comprehensive AMC and technical support available

Pharmaceutical Chemical Industry Effluent Treatment Plants from Aeolus Trade Information

- Minimum Order Quantity

- 1 Plant

- Supply Ability

- 10 Plants Per Month

- Delivery Time

- 5 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Middle East, Asia, Africa, Eastern Europe

- Main Domestic Market

- Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, Uttarakhand, Daman and Diu, Gujarat, Madhya Pradesh, Maharashtra, Rajasthan, Dadra and Nagar Haveli, Jammu and Kashmir, Bihar, Sikkim, Pondicherry, Meghalaya, Chandigarh, West India, Mizoram, Delhi, Tripura, Assam, South India, Manipur, Uttar Pradesh, Kerala, North India, Punjab, Goa, East India, Telangana, Karnataka, Jharkhand, Tamil Nadu, Arunachal Pradesh, West Bengal, Andhra Pradesh, Haryana, Lakshadweep, All India, Central India, Odisha, Chhattisgarh

About Pharmaceutical Chemical Industry Effluent Treatment Plants from Aeolus

Pharmaceutical Industry Effluent Treatment plants from Aeolus

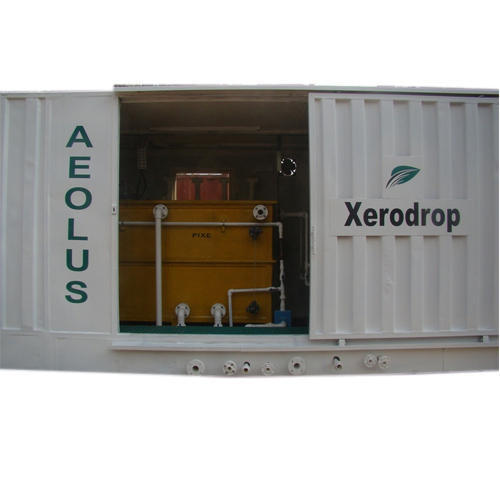

Aeolus is now a leader in complex effluent treatment to comply with most stringent discharge norms. Our XERODROP ETP is an extreme machine to treat complex effluents like that in the pharmaceutical & chemical industry without using any bacteria, chemicals and incineration.

For our XERODROP ETP we use technologies or combination of Technologies like Electro-Chemistry- Electro-coagulation followed by Electro-Oxidation, Advanced Oxidation Processes (UV/O3/H2O2) and natural extract botanical reagents.

XERODROP ETP is a plug & play compact system based on electro-chemistry. Electro-Coagulation and Electro-Oxidation are the major treatment stages. Treated water is by default disinfected. We also have ancillary systems like ozone, UV and finest filtration for best results with pharma ETP.

Aeolus XERODROP ETP has till now treated most complex effluents like Molasses Distillery Spent wash (COD 2, 20,000 ppm), H Acid & J Acid effluents (COD 1,80,000 ppm) and many such complex effluents. No chemicals are used to treat any of the above complex effluents!

Aeolus also undertakes modification of existing conventional pharmaceutical and chemical industry effluent treatment plants to meet the stringent discharge norms with minimum structural changes.

Other than wastewater treatment, we have some more interesting products for pharmaceutical and chemical industry viz.:

XERODROP AOP: Our advanced oxidation process based on photocatalytic oxidation is now ready to undertake all modification jobs for partially performing conventional ETP. XERODROP AOP also has application in disinfecting process water in pharma and chemical industry without adding any chemicals and chlorine. Cooling towers in pharma and chemical industry can be well managed with minimum chemicals (just 30% of normal requirement) when XERODROP AOP is installed at cooling towers in several industries.

AEOLUS OZONE: Our Ozone system has very wide applications in pharmaceutical /chemical industry viz.

- process water disinfection

- air contamination control in product packaging section

- CIP with minimum chemicals for plant and product storage and containers

- Oxidation in conventional ETP,

- pH reduction with highly alkaline effluent stream,

- H2S control in ETP & anaerobic bio-digesters,

- Cooling tower water treatment & disinfection-biofouling control

- air contamination control at chilling centre and cold storage

We also have various capacity UV radiation equipment to disinfect your process water and controlled air disinfection in critical manufacturing areas.

Contact us now for all your air, water and product disinfection requirement, Team Aeolus is happy to help you!

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Healthcare Hospital Pharma Industry Products Category

Complete Disinfection in Hospital and Operation Theatre with Ozone

Price 9000 INR / Plant

Minimum Order Quantity : 1 Plant

Properties : Electrical Appliances

Material : Ozone generator based Sterilizer and disinfection machine

Usage : Advanced Oxidation based disinfection and sterilization

Color : White or Stainless Steel Finish

Pharmaceutical Process Water Treatment by Ozone

Minimum Order Quantity : 1 Plant

Properties : Electrical Appliances

Material : Ozone generator based Sterilizer and disinfection machine

Usage : Advanced Oxidation based disinfection and sterilization

Color : White / Grey

ETP for Hospitals Healthcare Nursing Home Research Centers pathology lab by Aeolus

Price 150000 INR / Plant

Minimum Order Quantity : 1 Plant

Properties : Other, Ecofriendly, Nonbiological treatment, Low maintenance

Material : Stainless Steel/FRP construction

Usage : Effluent water treatment for healthcare facilities

Color : Grey/White

Hospital Acquired Infections HAI Prevention Control by Ozone

Price 24000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Properties : Electrical Appliances

Material : Metal

Usage : Advanced Oxidation based disinfection and sterilization

Color : White

Send Inquiry

Send Inquiry