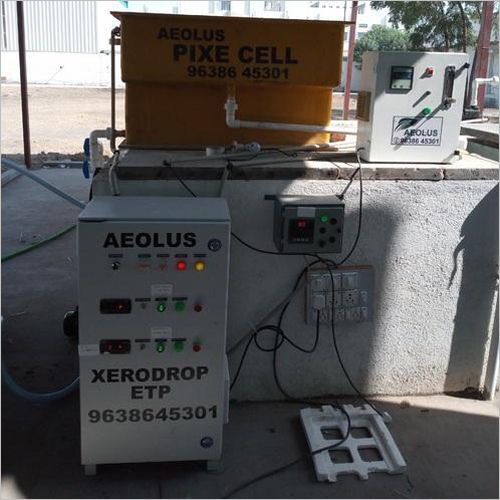

Modification of Existing ETP-STP with XERODROP AOP

Product Details:

- Frequency 50 Hz

- Water Out Conductivity <100 S/cm

- Power Consumption 2-10 kW (based on capacity)

- Recycle Rate Up to 95%

- Ph Level 6.5 8.5

- Efficiency (%) up to 98%

- Flow Rate Variable, up to 200 m3/hr

- Click to View more

Modification of Existing ETP-STP with XERODROP AOP Price And Quantity

- 1 Piece

- 45000 INR/Piece

Modification of Existing ETP-STP with XERODROP AOP Product Specifications

- <100 S/cm

- Centrifugal/Submersible

- 415 V AC

- 50 Hz

- 2-10 kW (based on capacity)

- < 60 dB

- Stainless Steel 304/316

- 6.5 8.5

- Customizable (1000 1,00,000 L/day)

- Up to 95%

- Variable, up to 200 m3/hr

- up to 98%

- Direct

- Fully Automatic

- XERODROP AOP (Advanced Oxidation Process), Modular Upgradation

- 1 100 MLD

- Multi-stage, Membrane & Media Filters

- Modular/Containerized

- ETP-STP Retrofit System

- Industrial Wastewater / Sewage

- Sewage, Industrial Effluent, Municipal Wastewater

- up to 99.5%

- Electric

- Advanced Oxidation Process (AOP), Quick Installation, Compact Footprint

Modification of Existing ETP-STP with XERODROP AOP Trade Information

- 10 - 100 Piece Per Month

- 2 Days

Product Description

Product details

Minimum Order Quantity | 1 Unit |

Type | Waste Water Treatment |

Feed Flow Rate | 50 m3/day,2000 m3/day,1000 m3/day,500 m3/day,100 m3/day |

Treatment Technique | Secondary Treatment |

Capacity Inlet Flow Rate | 100 m3/hour,10000 m3/hour,5000 m3/hour,2000 m3/hour,1000 m3/hour,500 m3/hour |

Water Source | Disinfection,Modification with advanced oxidation process for 100% results,modification of existing ETP/STP for achieving desired output,Waste Water Treatment |

Condition | New |

Treated Water Quality | Containerized Plug & Play |

Treatment Stages | Preliminary Treatment,Containerized Plug & Play,Modification,Wastewater Treatment Plant,As per CPCB norms,Primary Treatment |

Installation Type | Containerized Plug & Play,Prefabricated |

Control Module | Control Module Available |

Industry | All Industries with existing ETP/STP |

Function | Modification of existing low performing ETP/STP |

Brand | AEOLUS |

Material | FRP |

Automation Grade | Semi-Automatic |

Plant Type | Modification |

Application | Modification of all existing ETP/STP |

Seamless Upgradation with Minimal Disruption

XERODROP AOP retrofits seamlessly with existing ETP-STP setups, requiring minimal pre-treatment and offering plug-and-play installation. The modular, containerized design ensures that your operations experience little to no downtime, while quick installation and start-up in under 10 minutes minimize workflow interruptions. Our solution is fully customizable, adapting to capacities ranging from 1 to 100 MLD, making it suitable for a variety of industrial and municipal sites.

Advanced Oxidation for Maximum Purity

Utilizing Advanced Oxidation Process (AOP) technology, this system delivers exceptional effluent quality, achieving over 95% color removal and more than 90% COD/BOD reduction. Its automated oxidant dosing ensures optimal performance, while the multi-stage membrane and media filtration provide consistent water purity up to 99.5%. The treated water meets stringent CPCB discharge standards, and a recycle rate of up to 95% supports water conservation initiatives.

Smart Control and Low Maintenance

Integrated with PLC and IoT-enabled monitoring, XERODROP AOP provides real-time insight and remote operation options, enhancing process control and reliability. Its robust stainless steel construction ensures durability, and the system generates extremely low sludge, significantly reducing maintenance frequency. Optional annual maintenance contracts further streamline operations, offering peace of mind to operators.

FAQs of Modification of Existing ETP-STP with XERODROP AOP:

Q: How is the XERODROP AOP system integrated into existing ETP or STP infrastructure?

A: The XERODROP AOP system is designed as a retrofittable, plug-and-play solution. Its modular and compact build allows for quick integration into existing effluent or sewage treatment plants with minimal civil modification. Installation can be completed rapidly, and the system becomes operational in less than 10 minutes.Q: What are the key operational benefits of using XERODROP AOP in continuous mode?

A: Operating in continuous mode, XERODROP AOP ensures consistent water treatment with minimal manual intervention. The automated oxidant dosing, real-time IoT-based monitoring, and minimal pre-treatment requirement allow for uninterrupted operation and effective contaminant removal, ensuring high efficiency and steady compliance with CPCB discharge standards.Q: When is maintenance required, and what does it typically involve?

A: The XERODROP AOP system generates extremely low sludge and is engineered for low maintenance. Routine checks and servicing are straightforward, and operators can opt for an annual maintenance contract for added convenience. Maintenance primarily involves inspecting pumps, ensuring filter health, and software system checks.Q: Where can this upgraded system be applied?

A: This technology is suitable for upgrading existing industrial effluent and sewage treatment plants, as well as municipal wastewater facilities across India. Its customizable capacity (1 100 MLD) and modular design enable application at sites with varying treatment volumes and incoming water qualities.Q: What process features contribute to high treatment efficiency and water recovery?

A: The system employs advanced multi-stage filtration and AOP technology, offering over 95% color removal and more than 90% COD/BOD reduction. With optimized hydraulic retention times (under 2 hours) and high recycle rates (up to 95%), the process ensures rapid treatment, high purity, and efficient water reuse.Q: How does the system ensure operational safety and reliability?

A: XERODROP AOP includes built-in safety mechanisms such as automatic shutdown in the event of faults. PLC-based control integrates with IoT for reliable, real-time operation and monitoring, allowing remote diagnostics and timely alerts to prevent any process disruptions.Q: What are the main usage and sustainability benefits for plant operators?

A: Plant operators benefit from quick installation, low power consumption, flexible capacity, and significant reductions in footprint (up to 40% less than traditional systems). The advanced oxidation process delivers high-quality effluent suitable for recycling, supporting sustainability goals and efficient compliance with environmental standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free