Electro-Coagulation Electro-Oxidation Electrolytic System from Aeolus

Product Details:

- Treatment Technique Electro-Coagulation & Electro-Oxidation

- Automation Grade Semi Automatic

- Flow Rate 5 m/hr to 50 m/hr

- Water Source Industrial Effluent / Sewage / Waste Water

- Ph Level 5.5 - 9.5

- Material Mild Steel (MS), SS 304/316

- Membrane Size Custom modules

- Click to View more

Electro-Coagulation Electro-Oxidation Electrolytic System from Aeolus Price And Quantity

- 200000 INR/Plant

- 1 Plant

- 200000.00 - 2500000.00 INR/Plant

Electro-Coagulation Electro-Oxidation Electrolytic System from Aeolus Product Specifications

- 1 KLD to 1200 KLD

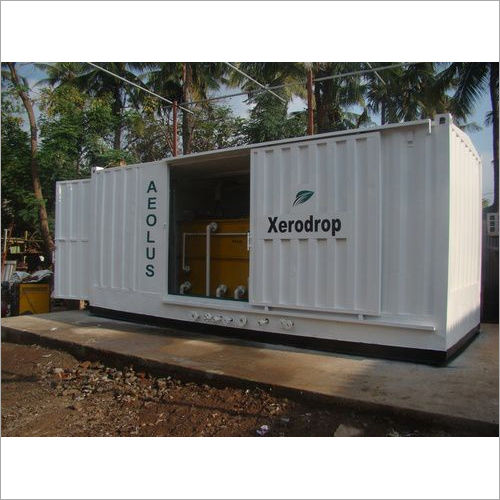

- Containerized / Skid Mounted

- Mild Steel (MS), SS 304/316

- Custom modules

- 5.5 - 9.5

- 5 kW - 300 kW (as per capacity)

- Module based (variable)

- Semi Automatic

- Waste Water Treatment, Effluent Treatment

- 850 mm x 650 mm x 1700 mm

- 1 year

- Normal Atmospheric

- Industrial Effluent / Sewage / Waste Water

- XERODROP- Non biological

- As per design

- Semi Automatic

- Blue-Grey

- 5 m/hr to 50 m/hr

- Effluent Treatment Plants

- Electro-Coagulation & Electro-Oxidation

- 900 kg (Approx)

- Electric

Electro-Coagulation Electro-Oxidation Electrolytic System from Aeolus Trade Information

- 4 Week

- Contact us for information regarding our sample policy

- Himachal Pradesh, Manipur, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, South India, East India, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, North India, Punjab, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

Product Description

Aeolus today is the leading supplier of Electro-coagulation and Electro-Oxidation with wide experience and sound technical know-how in the industry.

In the EC-Electro-coagulation process, the coagulant is generated in situ by electrolytic oxidation of an appropriate anode material. In this process, charged ionic species are removed from wastewater by allowing it to react with floccules of metallic hydroxides generated within the effluent.

EC could be of interest to Industries that generate wastewater containing oil wastes, dyes, suspended particles, chemical and mechanical polishing waste, and organic matter from landfill leachates, de-fluorination of water, synthetic detergent effluents, mine wastes and heavy metal containing solution.

Main Advantages OF THE ELECTRO-COAGULATION TECHNOLOGY

- Electro-coagulation requires simple equipment and is easy to operate.

- Sludge formed by EC is very low in quantity and can be dewatered quickly

- Flocs formed by EC are similar to chemical flocs, except that EC flocs contain less water and are more stable and therefore can be separated faster by filtration.

- The EC process has the advantage of removing the smallest colloidal particles, because the applied electric field sets them in faster motion, thereby facilitating the coagulation.

- The gas bubbles produced during the electrolysis can carry the pollutants to the top of the solution where it can be more easily removed.

INNOVATIVE ASPECTS OF THE TECHNOLOGY

- The Electro coagulation (EC) cell is controlled electrically and have no moving parts, thus requires less maintenance,

- The EC process avoids uses of chemicals and so there is no problem of neutralizing excess chemicals.

- EC produces effluents with less total dissolved solids (TDS) content as compared with chemical treatments

Electro coagulation EC when combined with physical treatments like sedimentation, settling, and fine filtration gives the best results in terms of water purification and treatment.

Electro coagulation when followed by Electro-oxidation or non-chemical oxidation of wastewater like Ozone and UV offers the best quality recyclable water from industrial or domestic wastewater.

Aeolus Electro-coagulation systems are till now supplied for various wastewater treatment including sewage, laundry effluent, hospital effluent, hotel & restaurant sewage, textile industry effluent, dairy effluent, chemical industry and cooling tower water treatment.

We offer treatability tests for your effluents.

Contact us for all your complex wastewater treatment requirements related to complexity of the effluent, space constraints, odour problems and mitigating the discharge norms. Aeolus has solutions for your problems!

Product Details:

|

Capacity Inlet Flow Rate (cubic meter/hour) |

1000 m3/hour, 5000 m3/hour, 2000 m3/hour, 10000 m3/hour, 100 m3/hour, 500 m3/hour |

|

Feed Flow Rate (cubic-meter/day) |

500 m3/day, 1000 m3/day, 100 m3/day, 50 m3/day, 2000 m3/day |

|

Automatic Grade |

Automatic |

|

Water Source |

Dairy Effluent, Cheese plant effluent, Ghee & Paneer Plant Effluent, Commercial Waste Water, Industrial Effluent, Municipal Sewage |

|

Treatment Technique |

AOP (Advanced Oxidation Process) based on Electro-Chemistry |

|

Plant Type |

Effluent Treatment Plant Hazardous Effluent Treatment, Sewage Treatment Plant, Effluent Treatment Plant, Waste Water Treatment Plant |

|

Treatment Stages |

Secondary Treatment, Primary Treatment, Disinfection, Preliminary Treatment |

|

Installation Type |

Prefabricated, Containerized Plug & Play |

|

Automation Grade |

Semi-Automatic |

|

Brand Name |

XERODROP ETP STP |

|

Usage |

Industrial Effluent Treatment plant for any industry |

|

Brand |

Aeolus XERODROP ETP STP |

Advanced Electrolytic Wastewater Treatment

The Aeolus Electro-Coagulation Electro-Oxidation system provides a comprehensive solution for industrial effluent treatment. With its robust XERODROP technology, it ensures significant reduction in organic and inorganic contaminants, supporting environmental compliance. Suited for a variety of industries, it streamlines operations while minimizing environmental impact.

Efficient and Sustainable Operation

Designed for operational efficiency, this system integrates low energy consumption, long service life, and advanced automation. Inline pH correction, reduced sludge generation, and a low-noise profile make it a practical, sustainable choice for continuous industrial wastewater management.

FAQs of Electro-Coagulation Electro-Oxidation Electrolytic System from Aeolus:

Q: How does the Aeolus Electrolytic System reduce sludge generation compared to conventional treatment methods?

A: The systems advanced electro-coagulation and electro-oxidation process actively breaks down contaminants while coagulating suspended solids, resulting in 6080% less sludge compared to traditional systems. This reduced sludge output simplifies disposal and lowers operational costs.Q: What types of industries can benefit from using this Electrolytic System?

A: This system is suitable for textile, pharmaceutical, chemical, and oil & gas industries, offering effective treatment for effluents containing heavy metals, high COD, and BOD levels, thus ensuring regulatory compliance and environmental safety.Q: When is it necessary to use inline pH adjustment in the process?

A: Inline pH correction should be used whenever influent water has a pH level outside the optimal range for coagulation and oxidation. The integrated pH adjustment ensures efficient contaminant removal and protects system components from corrosion.Q: Where can this system be installed for maximum efficiency?

A: Ideally, the system should be installed at the facilitys point of wastewater generation or before discharge, ensuring optimal treatment performance and minimal transport of untreated effluent within the site.Q: What are the main benefits of using the XERODROP non-biological technology?

A: XERODROP technology delivers consistent treatment without reliance on biological processes, which allows for stable operation, resilience to fluctuations in effluent quality, and compatibility with a broad range of industrial wastewater types.Q: How is the discharge quality maintained in the Aeolus system?

A: Through precise PLC or manual control, effective electrode selection, and integrated process monitoring, the system consistently yields high-quality, reusable discharge water in compliance with PCB norms.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free